Page 68 - Shale Shakers Drilling Fluid Systems

P. 68

HISTORICAL PERSPECTIVE 51

Originators of LINDA "K" Rotary Shale Extractor

C. F. HICKMAItf COMPANY

P. O. Box 1224 ALICE, TEXAS Phone 4-6901

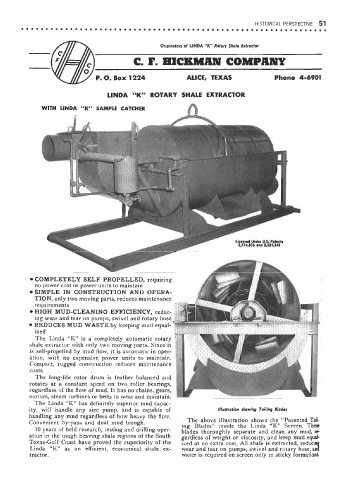

LINDA "K" ROTARY SHALE EXTRACTOR

• COMPLETELY SELF PROPELLED, requiring

no power cost or power units to maintain

• SIMPLE IN CONSTRUCTION AND OPERA-

TION, only two moving parts, reduces maintenance

requirements

• HIGH MUD-CLEANING EFFICIENCY, reduc-

ing- wear and tear on pumps, swivel and rotary hose

« REDUCES MUD WASTE by keeping mud equal-'

ized

The Linda "K" is a completely automatic rotary

shale extractor with only two moving parts. Since it

is self-propelled by mud flow, it is automatic in oper-

ation, with no expensive power units to maintain.

Compact, rugged construction reduces maintenance

costs,

The long-life rotor drum is feather balanced and

rotates at a constant speed on two roller bearings,

regardless of the flow of mud. It has no chains, gears,

motors, steam turbines or belts to wear and maintain.

The Linda "K" has definitely superior mud capac-

ity, will handle any size pump, and is capable of

handling any mud regardless of how heavy the flow.

Convenient by-pass and dual mud trough. The above illustration shows the "Patented Tail-

10 years of field research, testing and drilling oper- ing Blades" inside the Linda "K" Screen. These

blades thoroughly separate and clean any mud, re-

ation in the tough heaving shale regions of the South gardless of weight or viscosity, and keep mud equal-

Texas-Gulf Coast have proved the superiority of the ized at no extra cost. All shale is extracted, reducing

Linda "K" as an efficient, economical shale ex- wear and tear on pumps, swivel and rotary hose, and

tractor. water is required on screen only in sticky formations,