Page 70 - Shale Shakers Drilling Fluid Systems

P. 70

HISTORICAL PERSPECTIVE 53

MERCO CENTRIFUGAL CO.

San Francisco, California

OFFICES: ISO Green Street PLANT: 211 Green Street

Export Division: 74 Trinity Place, Slew York City, N. Y. Cable Address: LURCO

MERCO A-24 CONCENTRATOR

AND MERCO A-24 DESANDER

The Merco A-24 Separator is a versatile unit with a

20-year history of proven field performance. It has

been engineered to deliver continuous service in the

oil country, and with changes in speed, and disc-stack

the A-24 can be readily adapted for either the condi-

tioning of drilling mud, or in special cases, for the de-

sanding of drilling mud.

In anticipation of the abrasive materials that must be

handled on either of these operations, special wear-

resistant materials have been used throughout the

A-24 to minimize replacement costs.

MERCO A-24 CONCENTRATOR Operational Data

MERCO A-24 DESANDER

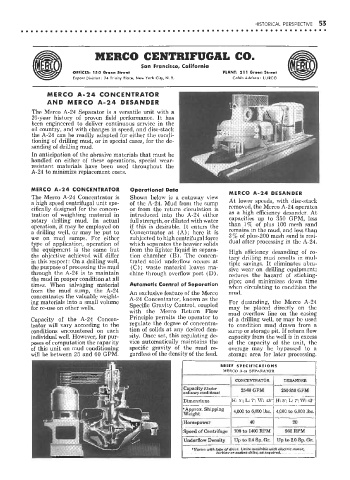

The Merco A-24 Concentrator is Shown below is a cutaway view

a high speed centrifugal unit spe- of the A-24. Mud from the sump At lower speeds, with disc-stack

cifically designed for the concen- or from the return circulation is removed, the Merco A-24 operates

tration of weighting material in introduced into the A-24 either as a high efficiency desander. At

rotary drilling mud. In actual full strength, or diluted with water capacities up to 350 GPM, less

operation, it may be employed on if this is desirable. It enters the than 1% of plus 100 mesh sand

a drilling well, or may be put to Concentrator at (A); here it is remains in the rnud, and less than

use on mud sumps. For either subjected to high centrifugal force 3 % of plus-200 rnesh sand is resi-

type of application, operation of which separates the heavier solids dual after processing in the A-24.

the equipment is the same but from the lighter liquid in separa- High efficiency desanding of ro-

the objective achieved will differ tion chamber (B). The concen- tary drilling mud results in mul-

in this respect: On a drilling well, trated solid underflow occurs at tiple savings. It eliminates abra-

the purpose of processing the mud (C); waste material leaves ma- sive wear on drilling equipment;

through the A-24 is to maintain chine through overflow port (D). reduces the hazard of sticking-

the mud in proper condition at all pipe; and minimizes down time

times. When salvaging material Automatic Control of Separation when circulating to condition the

from the mud sump, the A-24 An exclusive feature of the Merco mud.

concentrates the valuable weight- A-24 Concentrator, known as the

ing materials into a small volume Specific Gravity Control, coupled For desanding, the Merco A-24

for re-use on other wells. may be placed directly on the

with the Merco Return Flow mud overflow line on the casing

Capacity of the A-24 Concen- Principle permits the operator to of a drilling well, or may be used

trator will vary according to the regulate the degree of concentra- to condition mud drawn from a

conditions encountered on each tion of solids at any desired den- sump or storage pit. If return flow

individual well. However, for pur- sity. Once set, this regulating de- capacity from the well is in excess

poses of computation the capacity vice automatically maintains the of the capacity of the unit, the

of this unit on mud conditioning specific gravity of the mud re- overage may be bypassed to a

will be between 25 and 60 GPM. gardless of the density of the feed. storage area for later processing.

BRIEF SPECIFICATION S

MERCO A-24 SEPARATOR

CONCENTRATOR DESANDER

Capacity (Under 25-60 GPM 250-350 GPM

ordinary conditions)

Dimensions H: 5'; L: T\ W: 43" H: 5'; L: 7'; W: 43"

*Approx. Shipping 4,000 to 6,000 Ibs. 4,000 to 6,000 Ibs.

Weight

Horsepower 40 20

Speed of Centrifuge 700 to 1400 RPM 900 RPM

Underflow Density Up to 2.4 Sp. Gr. Up to 2.0 Sp. Gr.

* Varies with type of drive. Units available with electric motor,

turbine or engine drive, as required.