Page 75 - Shale Shakers Drilling Fluid Systems

P. 75

58 SHALE SHAKERS AND DRILLING FLUID SYSTEMS

HUTCHISON MANUFACTURING COMPANY

6609 Avenue U HOUSTON 11, TEXAS Phone: WAInut 6-7471

Subsidiary of Revere Electric Mfg. Co.

"RUMBA" SHALE SHAKERS

The NEW "RUMBA" THE MOST EFFECTIVE OF ALL SHALE SHAKERS.

Only "RUMBA" provides all the plus features. Check them for yourself.

Know why more "RUMBAS" are in use than all other Shale Shakers com-

bined.

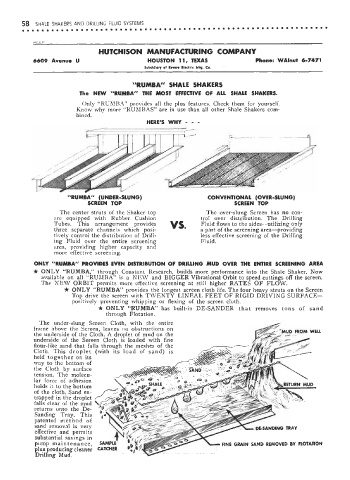

"RUMBA" (UNDER-SLUNG) CONVENTIONAL (OVER-SLUNG)

SCREEN TOP SCREEN TOP

The center struts of the Shaker top The over-slung Screen has no con-

are equipped with Rubber Cushion trol over distribution. The Drilling

Tubes. This arrangement provides VS. Fluid flows to the sides—utilizing only

three separate channels which posi- a part of the screening area—providing

tively control the distribution of Drill- less effective screening of the Drilling

ing Fluid over the entire screening Fluid.

area, providing higher capacity and

more effective screening.

ONLY "RUMBA" PROVIDES EVEN DISTRIBUTION OF DRILLING MUD OVER THE ENTIRE SCREENING AREA

* ONLY "RUMBA," through Constant Research, builds more performance into the Shale Shaker. Now

available on all "RUMBA" is a NEW and BIGGER Vibrational Orbit to speed cuttings off the screen.

The NEW ORBIT permits more effective screening at still higher RATES OF FLOW.

* ONLY "RUMBA" provides the longest screen cloth life. The four heavy struts on the Screen

Top drive the screen Avith TWENTY LINEAL FEET OF RIGID DRIVING SURFACE—

positively preventing whipping or flexing of the screen cloth.

* ONLY "RUMBA" has built-in DE-SANDER that removes tons of sand

through Flotation.

The under-slung Screen Cloth, with the entire

frame above the Screen, leaves no obstructions on

the underside of the Cloth. A droplet of mud on the

underside of the Screen Cloth is loaded with fine

flour-like sand that falls through the meshes of the

Cloth. This droplet (with its load of sand) is

held together on its

way to the bottom of

the Cloth by surface

tension. The molecu-

lar force of adhesion

holds it to the bottom

of the cloth. Sand en-

trapped in the droplet

falls clear of the mud

returns onto the De-

Sanding Tray. This

patented method of

sand removal is very

effective and permits

substantial savings in

pump maintenance,

plus producing cleaner

Drilling Mud.