Page 31 - Shigley's Mechanical Engineering Design

P. 31

bud29281_ch01_002-030.qxd 11/11/2009 5:35 pm Page 6 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

6 Mechanical Engineering Design

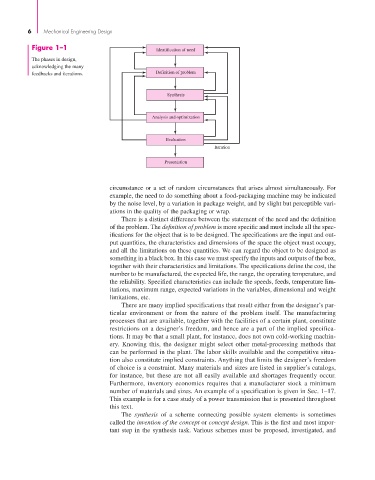

Figure 1–1 Identification of need

The phases in design,

acknowledging the many

feedbacks and iterations. Definition of problem

Synthesis

Analysis and optimization

Evaluation

Iteration

Presentation

circumstance or a set of random circumstances that arises almost simultaneously. For

example, the need to do something about a food-packaging machine may be indicated

by the noise level, by a variation in package weight, and by slight but perceptible vari-

ations in the quality of the packaging or wrap.

There is a distinct difference between the statement of the need and the definition

of the problem. The definition of problem is more specific and must include all the spec-

ifications for the object that is to be designed. The specifications are the input and out-

put quantities, the characteristics and dimensions of the space the object must occupy,

and all the limitations on these quantities. We can regard the object to be designed as

something in a black box. In this case we must specify the inputs and outputs of the box,

together with their characteristics and limitations. The specifications define the cost, the

number to be manufactured, the expected life, the range, the operating temperature, and

the reliability. Specified characteristics can include the speeds, feeds, temperature lim-

itations, maximum range, expected variations in the variables, dimensional and weight

limitations, etc.

There are many implied specifications that result either from the designer’s par-

ticular environment or from the nature of the problem itself. The manufacturing

processes that are available, together with the facilities of a certain plant, constitute

restrictions on a designer’s freedom, and hence are a part of the implied specifica-

tions. It may be that a small plant, for instance, does not own cold-working machin-

ery. Knowing this, the designer might select other metal-processing methods that

can be performed in the plant. The labor skills available and the competitive situa-

tion also constitute implied constraints. Anything that limits the designer’s freedom

of choice is a constraint. Many materials and sizes are listed in supplier’s catalogs,

for instance, but these are not all easily available and shortages frequently occur.

Furthermore, inventory economics requires that a manufacturer stock a minimum

number of materials and sizes. An example of a specification is given in Sec. 1–17.

This example is for a case study of a power transmission that is presented throughout

this text.

The synthesis of a scheme connecting possible system elements is sometimes

called the invention of the concept or concept design. This is the first and most impor-

tant step in the synthesis task. Various schemes must be proposed, investigated, and