Page 210 - Six Sigma for electronics design and manufacturing

P. 210

% Based on 100 at Concept Stage

120

100

80

60

40 Six Sigma Quality and Manufacturing Costs of Electronics Products 177

20

0

Concept Design Prototype Beta Production

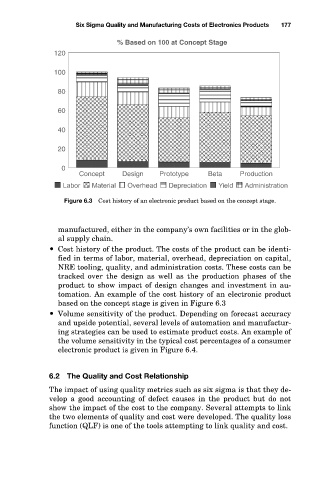

Figure 6.3 Cost history of an electronic product based on the concept stage.

manufactured, either in the company’s own facilities or in the glob-

al supply chain.

Cost history of the product. The costs of the product can be identi-

fied in terms of labor, material, overhead, depreciation on capital,

NRE tooling, quality, and administration costs. These costs can be

tracked over the design as well as the production phases of the

product to show impact of design changes and investment in au-

tomation. An example of the cost history of an electronic product

based on the concept stage is given in Figure 6.3

Volume sensitivity of the product. Depending on forecast accuracy

and upside potential, several levels of automation and manufactur-

ing strategies can be used to estimate product costs. An example of

the volume sensitivity in the typical cost percentages of a consumer

electronic product is given in Figure 6.4.

6.2 The Quality and Cost Relationship

The impact of using quality metrics such as six sigma is that they de-

velop a good accounting of defect causes in the product but do not

show the impact of the cost to the company. Several attempts to link

the two elements of quality and cost were developed. The quality loss

function (QLF) is one of the tools attempting to link quality and cost.