Page 149 - Soil Degradation, Conservation and Remediation

P. 149

138 5 Chemical Soil Degradation

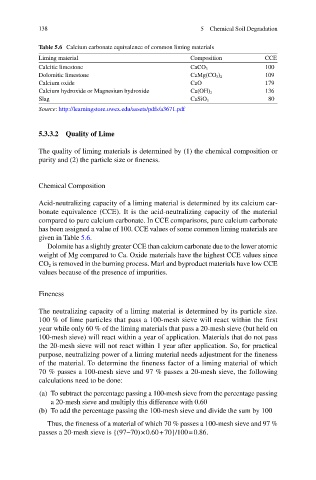

Table 5.6 Calcium carbonate equivalence of common liming materials

Liming material Composition CCE

Calcitic limestone CaCO 3 100

Dolomitic limestone CaMg(CO 3) 2 109

Calcium oxide CaO 179

Calcium hydroxide or Magnesium hydroxide Ca(OH) 2 136

Slag CaSiO 3 80

Source: http://learningstore.uwex.edu/assets/pdfs/a3671.pdf

5.3.3.2 Quality of Lime

The quality of liming materials is determined by (1) the chemical composition or

purity and (2) the particle size or fineness.

Chemical Composition

Acid-neutralizing capacity of a liming material is determined by its calcium car-

bonate equivalence (CCE). It is the acid-neutralizing capacity of the material

compared to pure calcium carbonate. In CCE comparisons, pure calcium carbonate

has been assigned a value of 100. CCE values of some common liming materials are

given in Table 5.6.

Dolomite has a slightly greater CCE than calcium carbonate due to the lower atomic

weight of Mg compared to Ca. Oxide materials have the highest CCE values since

CO 2 is removed in the burning process. Marl and byproduct materials have low CCE

values because of the presence of impurities.

Fineness

The neutralizing capacity of a liming material is determined by its particle size.

100 % of lime particles that pass a 100-mesh sieve will react within the first

year while only 60 % of the liming materials that pass a 20-mesh sieve (but held on

100- mesh sieve) will react within a year of application. Materials that do not pass

the 20-mesh sieve will not react within 1 year after application. So, for practical

purpose, neutralizing power of a liming material needs adjustment for the fineness

of the material. To determine the fineness factor of a liming material of which

70 % passes a 100-mesh sieve and 97 % passes a 20-mesh sieve, the following

calculations need to be done:

(a) To subtract the percentage passing a 100-mesh sieve from the percentage passing

a 20-mesh sieve and multiply this difference with 0.60

(b) To add the percentage passing the 100-mesh sieve and divide the sum by 100

Thus, the fineness of a material of which 70 % passes a 100-mesh sieve and 97 %

passes a 20-mesh sieve is {(97−70) × 0.60 + 70}/100 = 0.86.