Page 160 - Solid Waste Analysis and Minimization a Systems Approach

P. 160

138 THE GENERAL APPROACH FOR A SOLID WASTE ASSESSMENT

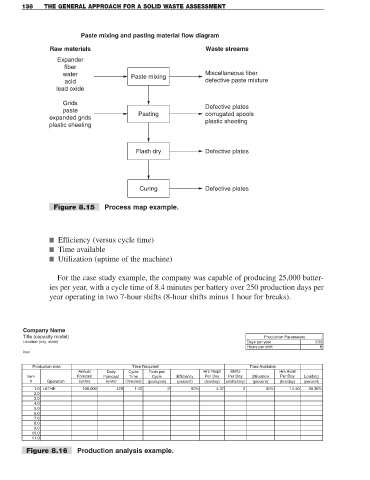

Paste mixing and pasting material flow diagram

Raw materials Waste streams

Expander

fiber

water Paste mixing Miscellaneous fiber

acid defective paste mixture

lead oxide

Grids

Defective plates

paste

Pasting corrugated spools

expanded grids

plastic sheeting

plastic sheeting

Flash dry Defective plates

Curing Defective plates

Figure 8.15 Process map example.

■ Efficiency (versus cycle time)

■ Time available

■ Utilization (uptime of the machine)

For the case study example, the company was capable of producing 25,000 batter-

ies per year, with a cycle time of 8.4 minutes per battery over 250 production days per

year operating in two 7-hour shifts (8-hour shifts minus 1 hour for breaks).

Company Name

Title (capacity model) Production Parameters

Location (city, state) Days per year 233

Hours per shift 8

Date:

Production area Time Required Time Available

Annual Daily Cycle Parts per Hrs Reqd Shifts Hrs Avail

Item Forecast Forecast Time Cycle Efficiency Per Day Per Day Utilization Per Day Loading

# Operation (units) (units) (minutes) (pcs/cycle) (percent) (hrs/day) (shifts/day) (percent) (hrs/day) (percent)

1.0 LATHE 100,000 429 1.10 2 90% 4.37 2 90% 14.40 30.36%

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

Figure 8.16 Production analysis example.