Page 77 - Solid Waste Analysis and Minimization a Systems Approach

P. 77

FUNDAMENTALS OF RECYCLING PROCESSES 55

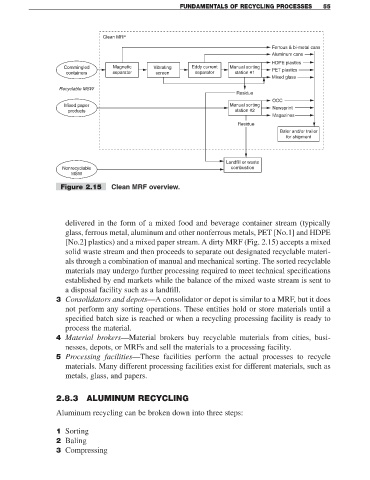

Clean MRF

Ferrous & bi-metal cans

Aluminum cans

HDPE plastics

Commingled Magnetic Vibrating Eddy current Manual sorting PET plastics

containers separator screen separator station #1

Mixed glass

Recyclable MSW

Residue

OCC

Mixed paper Manual sorting

products station #2 Newsprint

Magazines

Residue

Baler and/or trailer

for shipment

Landfill or waste

Nonrecyclable combustion

MSW

Figure 2.15 Clean MRF overview.

delivered in the form of a mixed food and beverage container stream (typically

glass, ferrous metal, aluminum and other nonferrous metals, PET [No.1] and HDPE

[No.2] plastics) and a mixed paper stream. A dirty MRF (Fig. 2.15) accepts a mixed

solid waste stream and then proceeds to separate out designated recyclable materi-

als through a combination of manual and mechanical sorting. The sorted recyclable

materials may undergo further processing required to meet technical specifications

established by end markets while the balance of the mixed waste stream is sent to

a disposal facility such as a landfill.

3 Consolidators and depots—A consolidator or depot is similar to a MRF, but it does

not perform any sorting operations. These entities hold or store materials until a

specified batch size is reached or when a recycling processing facility is ready to

process the material.

4 Material brokers—Material brokers buy recyclable materials from cities, busi-

nesses, depots, or MRFs and sell the materials to a processing facility.

5 Processing facilities—These facilities perform the actual processes to recycle

materials. Many different processing facilities exist for different materials, such as

metals, glass, and papers.

2.8.3 ALUMINUM RECYCLING

Aluminum recycling can be broken down into three steps:

1 Sorting

2 Baling

3 Compressing