Page 222 - Standard Handbook Of Petroleum & Natural Gas Engineering

P. 222

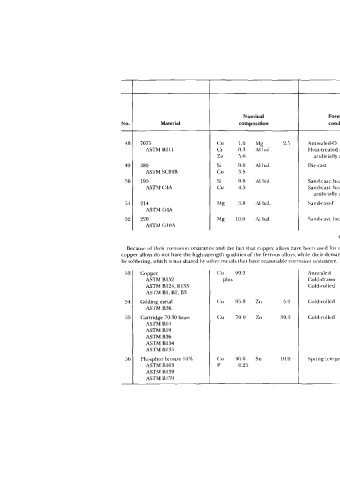

Typical mechanical properties

Yield

strength Tensile

Nominal Form and (0.2% Offset), SIrengIh, Elongation, Iardness,

Material composition condition 1000 Ib/sq in. 1000 lb/q in inZin.,% Brinell Comments

Cti 1.6 Mg 2.5 Annealed-O 17 60 High strength, good

ASTM B211 Cr 0.3 AI ha1 Heat-treated and corrosion resistance

Zn 5.6 artifirially aged-TR 11 150

SI 9.0 AI bal. Dir-cast '1 - Ceneral purpose die-canting

ASTM SC84B Cu 3.5

Si 0.8 AI bal. Sand-cast: hcal-treated-T4 8.5 60 Structural elcments, aircratt,

ASTM (:4A cu 4.5 Sandiast: hat-treated and and machinrb

artitirially aged-T6 7 75

Mg 9.8 .4l bal. Sandcast-F 9 50 Chemical equipmmr. marine

hardware, architectural

Mg 10.0 AI bal. Sandcat: heal-tredtrd-T4 16 75 Strength with shock

resistance: aircraft

COPPER ALLLOE

Because of their corrosion resistance and the fact that copper alloys have been used for niany thousands of years, the number of copper alloys available is second only to the ferrous alloys. In general

copper alloys do not have the highstrength qualmes of the frrrous alloys, while their density is comparable. The cost per strength-wenght ratio is high; however. thry have the advantagr of ease ofjoining

hv soldering, which is not shared hy other metals that have reasonable corrosion resistance.

53 Gopper <:u 99.9 Annealed 10 32 42 Bus-bars, switches,

ASTM B152 plus Cold-drawn 40 45 YO architectiiral, roofing,

ASTM 8124, R133 Cold-rolled 40 46 IO0 scrrrns cn

ASTM Bl,B2, B3 n

54 Gilding metal (:it 95.0 Zn 5.0 (:old-rolled 50 56 114 (:omage, ammunition

ASTM B36

35 Cartridge 70-30 bras\ Cu 70.0 Zn 30.0 Cold-rolled 6.7 76 155 Good cold-working

ASTM B14 properites: radiator co\prs, %

ASTM B19 hardwarp, clectrical z

ASTM B36 E

ASTM B134

ASTM 6135 3.

5f Phosphor bronrr 10% (:u 90.0 Sn 10.0 Sp, ,ng trmprr - I22 241 Good "I" ing qnalit,ps, E

v1

ASTM 8103 P 0.25 high-fatigue srrengrh

ASTM B139

z

- ASTM B159 N