Page 217 - Standard Handbook Of Petroleum & Natural Gas Engineering

P. 217

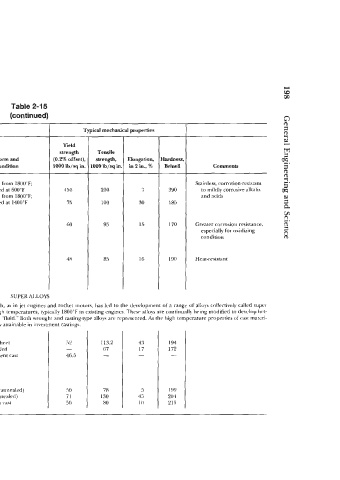

Table 2-15

(continued)

Typical mechanical properties

Nominal Form and lardness

Material composition condition Brinell Comments

~~

Carl 12 Cr alloy (a-15) C 0.15 Mn 1.00 Air-cooled from 1800°F Stainless, corrosion-resistant

rnax max tempered at 600'F 7 390 to mildly corrosive alkalis

Si 150 Cr 11.5- Air-cooled from 1800°F and acids

max 14 tempered at 1400°F 30 185

Ni 1.00 Fe bal.

max

28 Cast 29 9 alloy (CE-30) C 0.30 Mn 1.50 A? cast 15 170 Greater corrosion resistance,

ASTM A296 63T rnax max especially for oxidizing

SI 2.00 Cr 26-30 condition

max Fe hal.

Ni 8-11

29 Cast 28 7 alloy (HDj C 0.50 Mn 1.50 As cat 16 190 Heat-resistant

ASTM A297-63T max niax

Si 2.00 Cr 2630

rnax Fe hat.

Ni 4-7

SUPER AI.LOE

Thr advent of engineering applications reqwring high temperature ai high strength, as in jet engines and rocker nmtors, has led to the ieloprnrnt of a range of alloys collectively called super

alloys. These alloys require excellent resistance to oxidation together with strength at high temperatures, typically 1800°F in existing engrner These alloys are continually hwng modified to drvelop bet-

ter specific properties, and therefore entries in this group of alloys should be considered "fluid." Both wrought arid casting-typz alloys are represcntrd. As the high temperature properties of cdSt materi-

als improve, these alloys hrrome mor? attractive, sirice great dimensional precision is now atrainable in investment castings.

NICKEL BASE

Haytelloy X co 1.5 Fe 18.5 Wrought sheet 52 113.2 43 194

max Mo 9.0 Mill-annealed - 67 17 172

Cr 22.0 C 0.15 AI investment cast 46.5 - - -

M' 0.6 max

c 020 (wrought)

max Ni bal.

(Cast)

Ha*trllov c Cr 16.0 Fe 6.0 Sand-cast (annzalrdj 50 717 3 1!J9

W 4.0 c 0.15 Rolled (annealed) 71 130 45 204

Mo 17.0 Inax Irrvestment ras 50 80 1 0 215

Ni hal.