Page 213 - Standard Handbook Of Petroleum & Natural Gas Engineering

P. 213

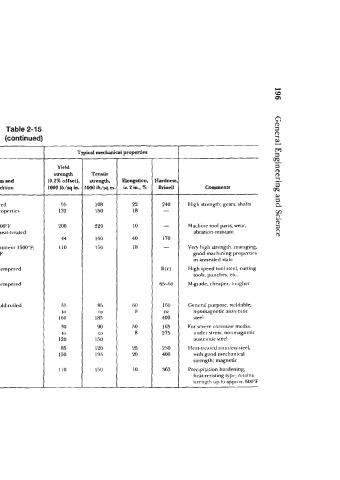

Table 2-15

- (continued)

Typical mechvlical properties

-

Yield

shen%h

Nominal Form and (0.2% offset) tvdoes

No. Material composition condition 10001b/sqin Brinell Commeno

-

10 AIS1 4140 C 0.40 Si 0.3 Fully-tempered 95 108 22 240 High strength; gears, shafts

-

Cr 1.0 Mo 0.2 Optimum properties 132 150 18

Mn 0.9

11 12% Manganese steel 12% Mn c Tempered 600°F 200 220 10 - Machine tool pdro; wear,

Rolled and heat-treated abrasion-resistant

stock 44 160 40 170

12 VMCO 300 Ni 18.5 Ti 0.6 Solution treatment 1500°F: 110 I50 18 - Very high strength, maraging,

co 9.0 C 0.03 aged 900°F good machining properties

Ma 4.8 in annealed state

13 TI (AISI) w 18.0 V 1 .o Quenched; tempered R(c) High speed tool steel, cutting

Cr 4.0 C 0.7 tools, punches, etc.

14 M2 (AISI) W 6.5 Mo 5.0 Quenched; tempered 65-66 Mgrade, cheaper, tougher

Cr 40 C 0.85

V 2.0

15 Stainless steel type 304 Ni 90 c 0.08 Annealed; cold-rolled 35 85 60 160 General purpose, weldahle;

Cr 19.0 max to to 8 co nonmagnetic austenitic

160 185 400 steel

16 Stainless steel type 316 Cr 18.0 c 0.10 Annealed 30 90 50 165 For severe corrosive media,

Ni 11.0 max to to 8 275 under stress: nonmagnetic

Mo 2.5 Fe bal. 1 PO 150 austenitic steel

17 Suinless steel type 431 Cr 160 Si 1.0 Annealed 85 120 25 250 Heat-treated stainless steel,

Ni 2.0 C 0.20 Heat-trrated 150 195 20 400 with good mechanical

Mn 1.0 Fe hal. strengrh; magnetic

18 Stainless steel 17 4 PH Cr 17.0 Co 0.35 Annealrd 110 150 10 363 Precipitation hardening;

Ni 40 C 0.07 heat-resisting type; retains

- Cu 4.0 Fe hal. __ strength up to apprnx. 600°F