Page 214 - Standard Handbook Of Petroleum & Natural Gas Engineering

P. 214

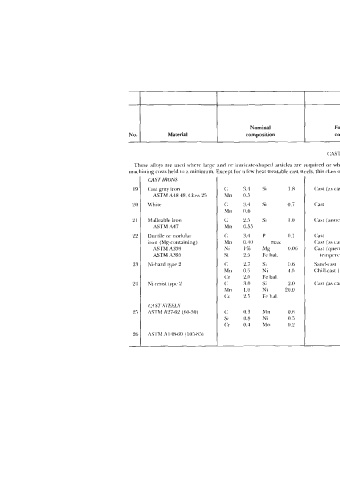

Typical mechanical properties

Yield

strength Tensile

Nominal Form and (0.2% offset), strength, Elongation, Hardness,

Material composition condition t 1000 Ib/sq in. 1000 Ib/sq in. in 2 in., R Brinell Comments

CAST IRONS .LVD CAST STEE1.S

These alloys are used whrrr largr and or intricate-shaped articles AIC required or where ow-all dimensional tolciancca are not critical. Thus thr iliiicle can he produced with the fabricatmi

machining costs held to a minimum. Except lor a frw heat-trratable cait strels, this claar of alloys does not demonstrate high-strength qualities.

CASTIRONS

I9 Cast pay iron c. 3.4 SI 1 .R Cast (as cast) 25 Engine blocks, fly-wheels.

I\STM AI8 48, Cl.t*s ?'I Mn 0.5 min gears, marhine-tool basca

?0 White c 3.4 SI 0.7 Caqt 25

Mn 0.6

2 1 Malleable iron c 2.5 9 1.0 52 Aotomotwea, nxlr brarings.

ASTM A47 Mn 0.55 track whrels, crankshaft5

22 Ductile or nodular c 5.4 P 0.1 Cast 70 kleavyduty machines, gears,

ti on (Mg-containing) Mri 0.40 mar Cast (as caal) 90 cams. crankshafts

ASTM A339 Ni 1% Mg 0.06 Cart (qnrnrhed

__

ASTM A395 Si 2.5 Fc bdl. tempered) IS5

con osion-resistancr

23 Ni-hard typr 2 c 2.7 Si 0.6 Sdrld<a<t .,:> Strength, with brat- and

Mn 05 NI 4.5 Chillxast (tetnpcied) 75

Cr 2.0 Fe bal.

24 Ni-rrnat typc 2 (: 3.0 Si 2.0 Cast (as cast) 27

Mn 1.0 NI 20.0

Cr 2.5 F? hdl.

(2.71 ,STfiEl.S

2.5 ASTM A27-ti2 (M-30) c: 0.3 Mn 0.6 ti0 I.ow alloy, nicdium Wcngth,

SI 0.8 Ni 0.5 general application 3

Cr 0.4 Mo 0 2

I05 High strength: structui~d 0,

applicatior~ z

I 8

w.

EL