Page 210 - Standard Handbook Of Petroleum & Natural Gas Engineering

P. 210

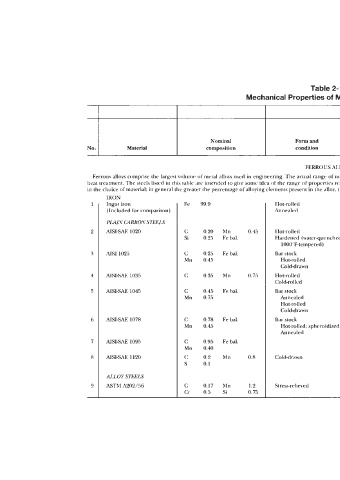

Table 2-15

Mechanical Properties of Metals and Alloys [lo]

I Typical mechanical propenies

Seld

Nominal Form and

No. Material composition condition Comments

FERROUS ALLOYS

Ferrous alloys comprise the largest volume of metal alloys used in engineering. The actual range of mechanical properties in any particular grade of alloy steel depends on the particular history and

heat treatment. The steels listed in this table are intended to give some idea of the range of properties readily obtainable. Many hundreds of steels are available. Cost is frequently an important criterion

io the choice of material; in general the greater the percentage of alloying elemenu present in the alloy, the greater will be the cost.

IRON

1 Ingot iron Fe 99.9 Hot-rolled 29 45 26 90

(Included for comparison) Annealed 19 38 45 67

PLAIN CARBON STEELS

2 AISISAE 1020 C 0.20 Mn 0.45 Hot-rolled 30 55 25 111 Bolts, cranltshafu, gears,

Si 0.25 Fe bal. Hardened (waterquenched. connecting rods; easily

1000°F-tempered) 62 90 25 179 weldable

3 AIS1 1025 C 0.25 Fe bal Bar stock

Mn 0.45 Hot-rolled 32 58 25 116

Colddrawn 54 64 15 126

4 AISISAE 1035 C 0.35 Mn 0.75 Hot-rolled 39 72 18 143 Mediumstrength, engineering

Cold-rolled 67 80 12 163 steel

5 AISISAE 1045 C 0.45 Fe bal Bar stock

Mn 0.75 Annealed 73 80 12 170

Hot-rolled 45 82 16 163

Colddrawn 77 91 12 179

6 AISISAE 1078 C 0.78 Fehal Bar stock

Mn 0.45 Hot-rolled; spheroidized 55 100 12 207

Annealed 72 94 10 192

7 AISISAE 1095 C 0.95 Fe bal.

Mn 0.40

8 AISISAE 1120 C 0.2 Mn 0.8 Colddrawn 58 69 - 137 Free-cutting, leaded,

s 0.1 resulphurized steel: high-

speed, automatic machining

ALLOY STEELS

9 ASTM A202/56 C 0.17 Mn 1.2 Stressrelieved 45 75 18 - Low alloy; boilers, pressure

- Cr 0.5 Si 0.75 vessels