Page 367 - Standard Handbook Petroleum Natural Gas Engineering VOLUME2

P. 367

Enhanced Oil Recovery Methods 399

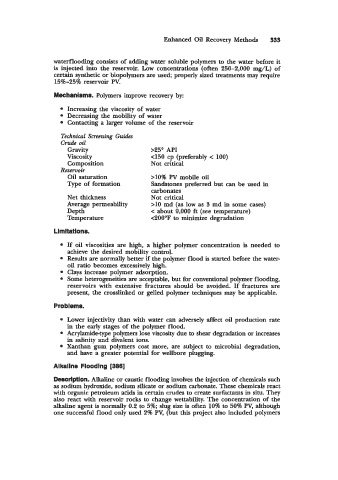

waterflooding consists of adding water soluble polymers to the water before it

is injected into the reservoir. Low concentrations (often 250-2,000 mg/L) of

certain synthetic or biopolymers are used; properly sized treatments may require

1596-2596 reservoir PV.

Mechanisms. Polymers improve recovery by:

Increasing the viscosity of water

Decreasing the mobility of water

Contacting a larger volume of the reservoir

Technical Smming Guides

cmtde oil

Gravity >25" API

Viscosity 450 cp (preferably < 100)

Composition Not critical

Reservoir

Oil saturation >lo% PV mobile oil

Type of formation Sandstones preferred but can be used in

carbonates

Net thickness Not critical

Average permeability >10 md (as low as 3 md in some cases)

Depth c about 9,000 ft (see temperature)

Temperature ~200°F to minimize degradation

Limitations.

If oil viscosities are high, a higher polymer concentration is needed to

achieve the desired mobility control.

Results are normally better if the polymer flood is started before the water-

oil ratio becomes excessively high.

Clays increase polymer adsorption.

Some heterogeneities are acceptable, but for conventional polymer flooding,

reservoirs with extensive fractures should be avoided. If fractures are

present, the crosslinked or gelled polymer techniques may be applicable.

Problems.

Lower injectivity than with water can adversely affect oil production rate

in the early stages of the polymer flood.

Acrylamidetype polymers lose viscosity due to shear degradation or increases

in salinity and divalent ions.

Xanthan gum polymers cost more, are subject to microbial degradation,

and have a greater potential for wellbore plugging.

Alkaline Flooding [386]

Description. Alkaliie or caustic flooding involves the injection of chemicals such

as sodium hydroxide, sodium silicate or sodium carbonate. These chemicals react

with organic petroleum acids in certain crudes to create surfactants in situ. They

also react with reservoir rocks to change wettability. The concentration of the

alkaline agent is normally 0.2 to 5% slug size is often 10% to 50% FV, although

one successful flood only used 9% PV, (but this project also included polymers