Page 369 - Standard Handbook Petroleum Natural Gas Engineering VOLUME2

P. 369

Enhanced Oil Recovery Methods 335

a producing well, and air injection is then switched to adjacent wells; however,

no successful field trials have been completed for reverse combustion.

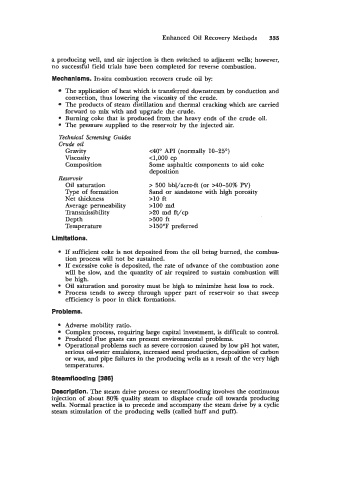

Mechanisms. In-situ combustion recovers crude oil by:

The application of heat which is transferred downstream by conduction and

convection, thus lowering the viscosity of the crude.

The products of steam distillation and thermal cracking which are carried

forward to mix with and upgrade the crude.

Burning coke that is produced from the heavy ends of the crude oil.

The pressure supplied to the reservoir by the injected air.

Technical Screening Guides

crude oil

Gravity c40" API (normally 10-25")

Viscosity <1,000 cp

Composition Some asphaltic components to aid coke

deposition

Reservoir

Oil saturation > 500 bbl/acre-ft (or >40-50% PV)

Type of formation Sand or sandstone with high porosity

Net thickness >10 ft

Average permeability >lo0 md

Transmissibility >20 md ft/cp

Depth >500 ft

Temperature >150"F preferred

Limitations.

If sufficient coke is not deposited from the oil being burned, the combus-

tion process will not be sustained.

If excessive coke is deposited, the rate of advance of the combustion zone

will be slow, and the quantity of air required to sustain combustion will

be high.

Oil saturation and porosity must be high to minimize heat loss to rock.

Process tends to sweep through upper part of reservoir so that sweep

efficiency is poor in thick formations.

Problems.

Adverse mobility ratio.

Complex process, requiring large capital investment, is difficult to control.

Produced flue gases can present environmental problems.

Operational problems such as severe corrosion caused by low pH hot water,

serious oil-water emulsions, increased sand production, deposition of carbon

or wax, and pipe failures in the producing wells as a result of the very high

temperatures.

Steamflooding [386]

Description. The steam drive process or steamf looding involves the continuous

injection of about 80% quality steam to displace crude oil towards producing

wells. Normal practice is to precede and accompany the steam drive by a cyclic

steam stimulation of the producing wells (called huff and puff).