Page 21 - Steam Turbines--Design, Applications, and Rerating by Heinz-Bloch, Murari-Singh

P. 21

2 Chapter One

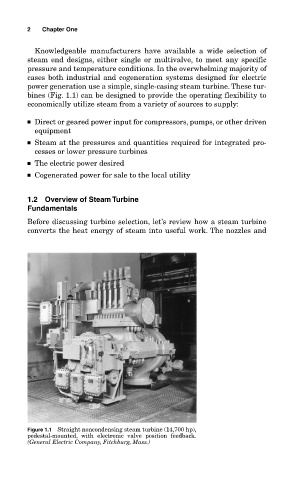

Knowledgeable manufacturers have available a wide selection of

steam end designs, either single or multivalve, to meet any specific

pressure and temperature conditions. In the overwhelming majority of

cases both industrial and cogeneration systems designed for electric

power generation use a simple, single-casing steam turbine. These tur-

bines (Fig. 1.1) can be designed to provide the operating flexibility to

economically utilize steam from a variety of sources to supply:

■ Direct or geared power input for compressors, pumps, or other driven

equipment

■ Steam at the pressures and quantities required for integrated pro-

cesses or lower pressure turbines

■ The electric power desired

■ Cogenerated power for sale to the local utility

1.2 Overview of Steam Turbine

Fundamentals

Before discussing turbine selection, let’s review how a steam turbine

converts the heat energy of steam into useful work. The nozzles and

Figure 1.1 Straight noncondensing steam turbine (14,700 hp),

pedestal-mounted, with electronic valve position feedback.

(General Electric Company, Fitchburg, Mass.)