Page 246 - Steam Turbines Design, Applications, and Rerating

P. 246

Reaction vs. Impulse Type Steam Turbines 225

flow) can be predicted with sufficient accuracy; blade failures are

almost entirely due to dynamic stresses.

Although in theory no set of blades can be made free of resonance, it

is possible to design and manufacture blading so that dangerous reso-

nances are avoided and no unacceptably high stresses occur. The nec-

essary conditions can be considered separately for stages with partial

and full admission.

Control stage. Conditions in the control stage, with partial admission,

are essentially the same for both types of machines. Extensive studies

show that attention must be paid to the following points to ensure that

this stage functions reliably:

■ Low stress level

■ Careful design of the blade fixing

■ Blades joined to form segments, or packets

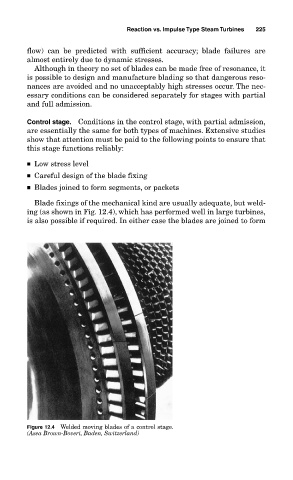

Blade fixings of the mechanical kind are usually adequate, but weld-

ing (as shown in Fig. 12.4), which has performed well in large turbines,

is also possible if required. In either case the blades are joined to form

Figure 12.4 Welded moving blades of a control stage.

(Asea Brown-Boveri, Baden, Switzerland)