Page 295 - Steam Turbines Design, Applications, and Rerating

P. 295

272 Chapter Fourteen

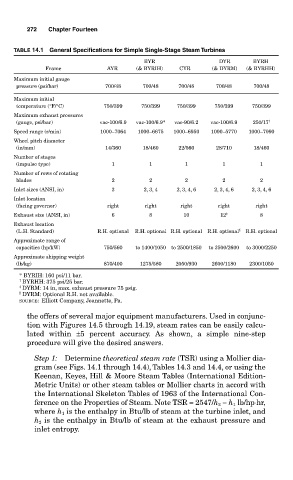

TABLE 14.1 General Specifications for Simple Single-Stage Steam Turbines

BYR DYR BYRH

Frame AYR (& BYRIH) CYR (& DYRM) (& BYRHH)

Maximum initial gauge

pressure (psi/bar) 700/48 700/48 700/48 700/48 700/48

Maximum initial

temperature (°F/°C) 750/399 750/399 750/399 750/399 750/399

Maximum exhaust pressures

(gauge, psi/bar) vac-100/6.9 vac-100/6.9* vac-90/6.2 vac-100/6.9 250/17 †

Speed range (r/min) 1000–7064 1000–6675 1000–6950 1000–5770 1000–7090

Wheel pitch diameter

(in/mm) 14/360 18/460 22/560 28/710 18/460

Number of stages

(impulse type) 1 1 1 1 1

Number of rows of rotating

blades 2 2 2 2 2

Inlet sizes (ANSI, in) 3 2, 3, 4 2, 3, 4, 6 2, 3, 4, 6 2, 3, 4, 6

Inlet location

(facing governor) right right right right right

Exhaust size (ANSI, in) 6 8 10 12 ‡ 8

Exhaust location

(L.H. Standard) R.H. optional R.H. optional R.H. optional R.H. optional § R.H. optional

Approximate range of

capacities (hp/kW) 750/560 to 1400/1050 to 2500/1850 to 3500/2600 to 3000/2250

Approximate shipping weight

(lb/kg) 870/400 1275/580 2050/930 2600/1180 2300/1050

* BYRIH: 160 psi/11 bar.

† BYRHH: 375 psi/25 bar.

‡ DYRM: 14 in, max. exhaust pressure 75 psig.

§ DYRM: Optional R.H. not available.

SOURCE: Elliott Company, Jeannette, Pa.

the offers of several major equipment manufacturers. Used in conjunc-

tion with Figures 14.5 through 14.19, steam rates can be easily calcu-

lated within ±5 percent accuracy. As shown, a simple nine-step

procedure will give the desired answers.

Step 1: Determine theoretical steam rate (TSR) using a Mollier dia-

gram (see Figs. 14.1 through 14.4), Tables 14.3 and 14.4, or using the

Keenan, Keyes, Hill & Moore Steam Tables (International Edition-

Metric Units) or other steam tables or Mollier charts in accord with

the International Skeleton Tables of 1963 of the International Con-

ference on the Properties of Steam. Note TSR = 2547/h 2 − h 1 lb/hp⋅hr,

where h 1 is the enthalpy in Btu/lb of steam at the turbine inlet, and

h 2 is the enthalpy in Btu/lb of steam at the exhaust pressure and

inlet entropy.