Page 332 - Steam Turbines Design, Applications, and Rerating

P. 332

306 Chapter Fourteen

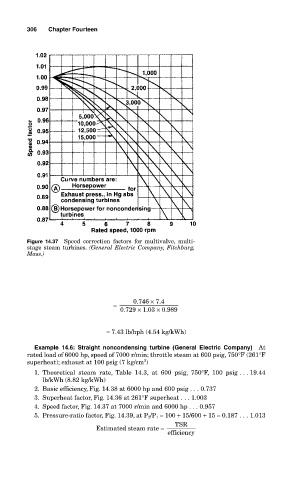

Figure 14.37 Speed correction factors for multivalve, multi-

stage steam turbines. (General Electric Company, Fitchburg,

Mass.)

0.746 × 7.4

=

0.729 × 1.03 × 0.989

= 7.43 lb/hph (4.54 kg/kWh)

Example 14.6: Straight noncondensing turbine (General Electric Company) At

rated load of 6000 hp, speed of 7000 r/min; throttle steam at 600 psig, 750°F (261°F

2

superheat); exhaust at 100 psig (7 kg/cm )

1. Theoretical steam rate, Table 14.3, at 600 psig, 750°F, 100 psig . . . 19.44

lb/kWh (8.82 kg/kWh)

2. Basic efficiency, Fig. 14.38 at 6000 hp and 600 psig . . . 0.737

3. Superheat factor, Fig. 14.36 at 261°F superheat . . . 1.003

4. Speed factor, Fig. 14.37 at 7000 r/min and 6000 hp . . . 0.957

5. Pressure-ratio factor, Fig. 14.39, at P 2 /P 1 = 100 + 15/600 + 15 = 0.187... 1.013

TSR

Estimated steam rate =

efficiency