Page 361 - Steam Turbines Design, Applications, and Rerating

P. 361

Rerates, Upgrades, and Modifications 335

Figure 16.5 Two variations of a brush seal installation. (Advanced Turbomachine,

LLC)

Labyrinth teeth can be damaged by rubs, especially during start-up

or coast-down when the turbine rotor passes through a lateral critical

speed. Leakage may also occur as a result of rubs. Rubs may also occur

at start-up due to different rates of thermal expansion between the

seal and the rotor. The rub opens the clearance, results in leakage, and

reduces efficiency. Retractable packing, as illustrated in Fig. 16.6, is a

possible solution to this problem. The labyrinth ring is circumferen-

tially divided into segments that are spring-loaded to hold them apart

and give a very generous clearance. Once the turbine starts and steam

pressure builds up on the outside diameter of the seal, it overcomes the

spring pressure and closes the seal to normal clearance. During tur-

bine trips, steam pressure is reduced and the spring again opens the

clearance for coast-down. Reduction in leakage flow as a result of

improved seal design is illustrated in Fig. 16.7.

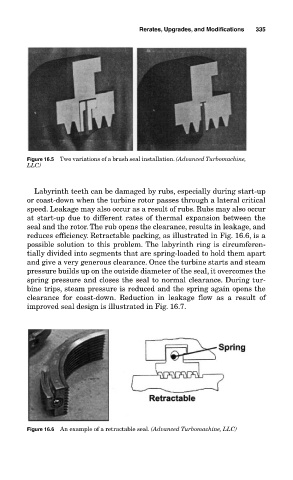

Figure 16.6 An example of a retractable seal. (Advanced Turbomachine, LLC)