Page 364 - Steam Turbines Design, Applications, and Rerating

P. 364

338 Chapter Sixteen

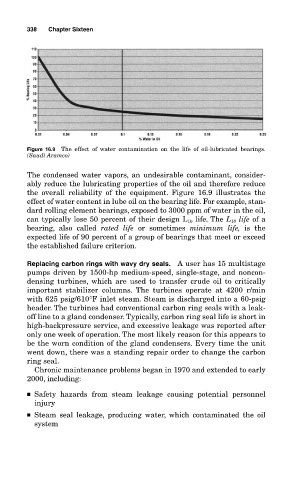

Figure 16.9 The effect of water contamination on the life of oil-lubricated bearings.

(Saudi Aramco)

The condensed water vapors, an undesirable contaminant, consider-

ably reduce the lubricating properties of the oil and therefore reduce

the overall reliability of the equipment. Figure 16.9 illustrates the

effect of water content in lube oil on the bearing life. For example, stan-

dard rolling element bearings, exposed to 3000 ppm of water in the oil,

can typically lose 50 percent of their design L 10 life. The L 10 life of a

bearing, also called rated life or sometimes minimum life, is the

expected life of 90 percent of a group of bearings that meet or exceed

the established failure criterion.

Replacing carbon rings with wavy dry seals. A user has 15 multistage

pumps driven by 1500-hp medium-speed, single-stage, and noncon-

densing turbines, which are used to transfer crude oil to critically

important stabilizer columns. The turbines operate at 4200 r/min

with 625 psig/610°F inlet steam. Steam is discharged into a 60-psig

header. The turbines had conventional carbon ring seals with a leak-

off line to a gland condenser. Typically, carbon ring seal life is short in

high-backpressure service, and excessive leakage was reported after

only one week of operation. The most likely reason for this appears to

be the worn condition of the gland condensers. Every time the unit

went down, there was a standing repair order to change the carbon

ring seal.

Chronic maintenance problems began in 1970 and extended to early

2000, including:

■ Safety hazards from steam leakage causing potential personnel

injury

■ Steam seal leakage, producing water, which contaminated the oil

system