Page 18 - Structural Steel Designers Handbook AISC, AASHTO, AISI, ASTM, and ASCE-07 Design Standards

P. 18

Brockenbrough_Ch01.qxd 9/29/05 4:59 PM Page 1.16

PROPERTIES OF STRUCTURAL STEELS AND EFFECTS OF STEELMAKING AND FABRICATION

1.16 CHAPTER ONE

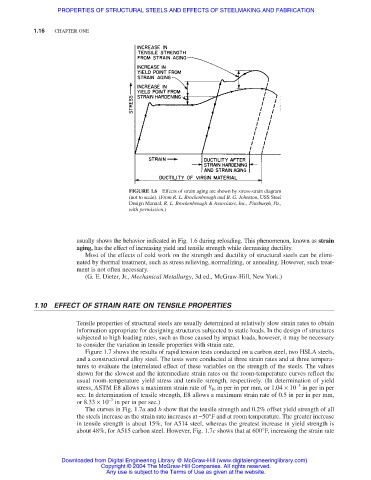

FIGURE 1.6 Effects of strain aging are shown by stress-strain diagram

(not to scale). (From R. L. Brockenbrough and B. G. Johnston, USS Steel

Design Manual, R. L. Brockenbrough & Associates, Inc., Pittsburgh, Pa.,

with permission.)

usually shows the behavior indicated in Fig. 1.6 during reloading. This phenomenon, known as strain

aging, has the effect of increasing yield and tensile strength while decreasing ductility.

Most of the effects of cold work on the strength and ductility of structural steels can be elimi-

nated by thermal treatment, such as stress relieving, normalizing, or annealing. However, such treat-

ment is not often necessary.

(G. E. Dieter, Jr., Mechanical Metallurgy, 3d ed., McGraw-Hill, New York.)

1.10 EFFECT OF STRAIN RATE ON TENSILE PROPERTIES

Tensile properties of structural steels are usually determined at relatively slow strain rates to obtain

information appropriate for designing structures subjected to static loads. In the design of structures

subjected to high loading rates, such as those caused by impact loads, however, it may be necessary

to consider the variation in tensile properties with strain rate.

Figure 1.7 shows the results of rapid tension tests conducted on a carbon steel, two HSLA steels,

and a constructional alloy steel. The tests were conducted at three strain rates and at three tempera-

tures to evaluate the interrelated effect of these variables on the strength of the steels. The values

shown for the slowest and the intermediate strain rates on the room-temperature curves reflect the

usual room-temperature yield stress and tensile strength, respectively. (In determination of yield

−3

1

stress, ASTM E8 allows a maximum strain rate of / 16 in per in per mm, or 1.04 × 10 in per in per

sec. In determination of tensile strength, E8 allows a maximum strain rate of 0.5 in per in per mm,

−3

or 8.33 × 10 in per in per sec.)

The curves in Fig. 1.7a and b show that the tensile strength and 0.2% offset yield strength of all

the steels increase as the strain rate increases at −50°F and at room temperature. The greater increase

in tensile strength is about 15%, for A514 steel, whereas the greatest increase in yield strength is

about 48%, for A515 carbon steel. However, Fig. 1.7c shows that at 600°F, increasing the strain rate

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.