Page 66 - Structural Steel Designers Handbook AISC, AASHTO, AISI, ASTM, and ASCE-07 Design Standards

P. 66

Brockenbrough_Ch02.qxd 9/29/05 5:01 PM Page 2.28

FABRICATION AND ERECTION*

2.28 CHAPTER TWO

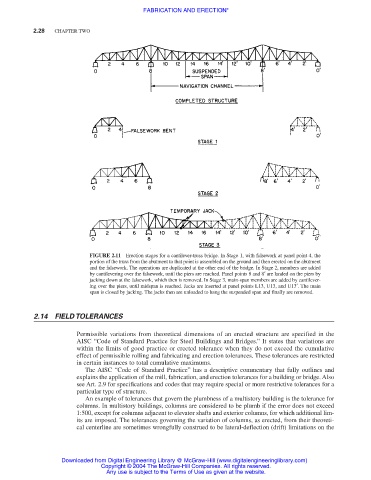

FIGURE 2.11 Erection stages for a cantilever-truss bridge. In Stage 1, with falsework at panel point 4, the

portion of the truss from the abutment to that point is assembled on the ground and then erected on the abutment

and the falsework. The operations are duplicated at the other end of the bridge. In Stage 2, members are added

by cantilevering over the falsework, until the piers are reached. Panel points 8 and 8′ are landed on the piers by

jacking down at the falsework, which then is removed. In Stage 3, main-span members are added by cantilever-

ing over the piers, until midspan is reached. Jacks are inserted at panel points L13, U13, and U13′. The main

span is closed by jacking. The jacks then are unloaded to hang the suspended span and finally are removed.

2.14 FIELD TOLERANCES

Permissible variations from theoretical dimensions of an erected structure are specified in the

AISC “Code of Standard Practice for Steel Buildings and Bridges.” It states that variations are

within the limits of good practice or erected tolerance when they do not exceed the cumulative

effect of permissible rolling and fabricating and erection tolerances. These tolerances are restricted

in certain instances to total cumulative maximums.

The AISC “Code of Standard Practice” has a descriptive commentary that fully outlines and

explains the application of the mill, fabrication, and erection tolerances for a building or bridge. Also

see Art. 2.9 for specifications and codes that may require special or more restrictive tolerances for a

particular type of structure.

An example of tolerances that govern the plumbness of a multistory building is the tolerance for

columns. In multistory buildings, columns are considered to be plumb if the error does not exceed

1:500, except for columns adjacent to elevator shafts and exterior columns, for which additional lim-

its are imposed. The tolerances governing the variation of columns, as erected, from their theoreti-

cal centerline are sometimes wrongfully construed to be lateral-deflection (drift) limitations on the

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.