Page 28 - Structural Steel Designers Handbook AISC, AASHTO, AISI, ASTM, and ASCE-07 Design Standards

P. 28

Brockenbrough_Ch01.qxd 9/29/05 4:59 PM Page 1.26

PROPERTIES OF STRUCTURAL STEELS AND EFFECTS OF STEELMAKING AND FABRICATION

1.26 CHAPTER ONE

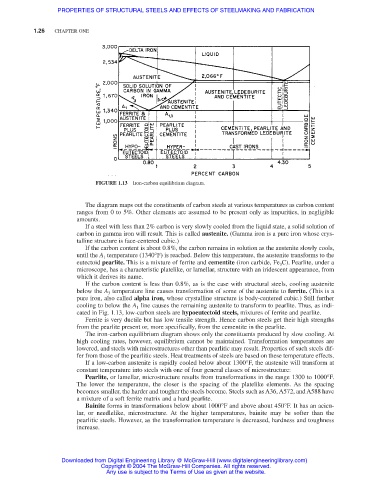

FIGURE 1.13 Iron-carbon equilibrium diagram.

The diagram maps out the constituents of carbon steels at various temperatures as carbon content

ranges from 0 to 5%. Other elements are assumed to be present only as impurities, in negligible

amounts.

If a steel with less than 2% carbon is very slowly cooled from the liquid state, a solid solution of

carbon in gamma iron will result. This is called austenite. (Gamma iron is a pure iron whose crys-

talline structure is face-centered cubic.)

If the carbon content is about 0.8%, the carbon remains in solution as the austenite slowly cools,

until the A 1 temperature (1340°F) is reached. Below this temperature, the austenite transforms to the

eutectoid pearlite. This is a mixture of ferrite and cementite (iron carbide, Fe 3 C). Pearlite, under a

microscope, has a characteristic platelike, or lamellar, structure with an iridescent appearance, from

which it derives its name.

If the carbon content is less than 0.8%, as is the case with structural steels, cooling austenite

below the A 3 temperature line causes transformation of some of the austenite to ferrite. (This is a

pure iron, also called alpha iron, whose crystalline structure is body-centered cubic.) Still further

cooling to below the A 1 line causes the remaining austenite to transform to pearlite. Thus, as indi-

cated in Fig. 1.13, low-carbon steels are hypoeutectoid steels, mixtures of ferrite and pearlite.

Ferrite is very ductile but has low tensile strength. Hence carbon steels get their high strengths

from the pearlite present or, more specifically, from the cementite in the pearlite.

The iron-carbon equilibrium diagram shows only the constituents produced by slow cooling. At

high cooling rates, however, equilibrium cannot be maintained. Transformation temperatures are

lowered, and steels with microstructures other than pearlitic may result. Properties of such steels dif-

fer from those of the pearlitic steels. Heat treatments of steels are based on these temperature effects.

If a low-carbon austenite is rapidly cooled below about 1300°F, the austenite will transform at

constant temperature into steels with one of four general classes of microstructure:

Pearlite, or lamellar, microstructure results from transformations in the range 1300 to 1000°F.

The lower the temperature, the closer is the spacing of the platelike elements. As the spacing

becomes smaller, the harder and tougher the steels become. Steels such as A36, A572, and A588 have

a mixture of a soft ferrite matrix and a hard pearlite.

Bainite forms in transformations below about 1000°F and above about 450°F. It has an acicu-

lar, or needlelike, microstructure. At the higher temperatures, bainite may be softer than the

pearlitic steels. However, as the transformation temperature is decreased, hardness and toughness

increase.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.