Page 314 - Sustainability in the Process Industry Integration and Optimization

P. 314

T y p i c a l P i t f a l l s a n d How t o Avo i d T h e m 291

110° 70° 110° 20°

Storage Storage

70° 20°

Cooler Cooler

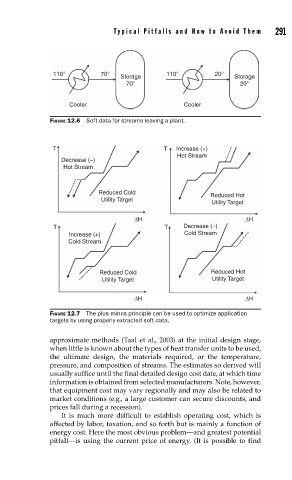

FIGURE 12.6 Soft data for streams leaving a plant.

T T Increase (+)

Hot Stream

Decrease (–)

Hot Stream

Reduced Cold Reduced Hot

Utility Target

Utility Target

ΔH ΔH

T T Decrease (–)

Increase (+) Cold Stream

Cold Stream

Reduced Cold Reduced Hot

Utility Target Utility Target

ΔH ΔH

FIGURE 12.7 The plus-minus principle can be used to optimize application

targets by using properly extracted soft data.

approximate methods (Taal et al., 2003) at the initial design stage,

when little is known about the types of heat transfer units to be used,

the ultimate design, the materials required, or the temperature,

pressure, and composition of streams. The estimates so derived will

usually suffice until the final detailed design cost date, at which time

information is obtained from selected manufacturers. Note, however,

that equipment cost may vary regionally and may also be related to

market conditions (e.g., a large customer can secure discounts, and

prices fall during a recession).

It is much more difficult to establish operating cost, which is

affected by labor, taxation, and so forth but is mainly a function of

energy cost. Here the most obvious problem—and greatest potential

pitfall—is using the current price of energy. (It is possible to find