Page 152 - Materials Chemistry, Second Edition

P. 152

Ch004-P373623.qxd 3/26/07 4:46 PM Page 131

Sustainable Development and Environmental Reform

Continual improvement 131

Management Environment

review policy

Cleaner production

technology

• Source reduction

Checking and * Good housekeeping Planning

corrective action * Process changes • Environmental

• Monitoring and - Better process control aspects

measurement - Equipment modification • Legal and other

• Non-conformance - Technology change requirements

and corrective - Input material change • Objectives and

action • Recycling targets

• Records * On-site recycling • Environmental

• EMS audits * Off-site recycling management

• Product modification programs

Implementation and

operation

• Structure and responsibility

• Training, awareness and

competence

• Communication

• EMS documentation

• Document control

• Operational control

• Emergency

preparedness and

response

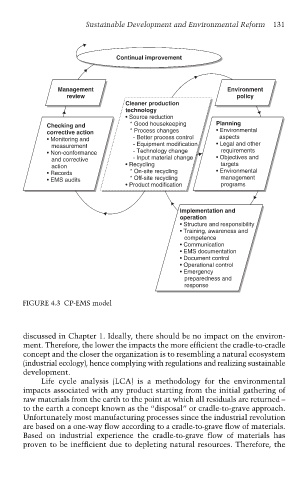

FIGURE 4.3 CP-EMS model

discussed in Chapter 1. Ideally, there should be no impact on the environ-

ment. Therefore, the lower the impacts the more efficient the cradle-to-cradle

concept and the closer the organization is to resembling a natural ecosystem

(industrial ecology), hence complying with regulations and realizing sustainable

development.

Life cycle analysis (LCA) is a methodology for the environmental

impacts associated with any product starting from the initial gathering of

raw materials from the earth to the point at which all residuals are returned –

to the earth a concept known as the “disposal” or cradle-to-grave approach.

Unfortunately most manufacturing processes since the industrial revolution

are based on a one-way flow according to a cradle-to-grave flow of materials.

Based on industrial experience the cradle-to-grave flow of materials has

proven to be inefficient due to depleting natural resources. Therefore, the