Page 70 - Materials Chemistry, Second Edition

P. 70

Ch002-P373623.qxd 3/22/07 5:27 PM Page 51

TABLE 2.17 Cleaner Production 51

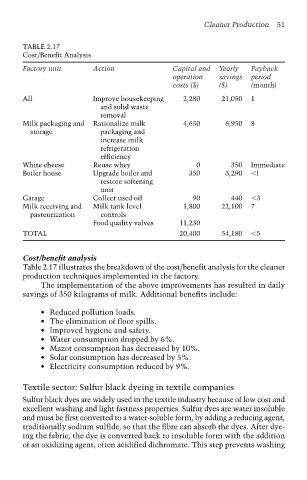

Cost/Benefit Analysis

Factory unit Action Capital and Yearly Payback

operation savings period

costs ($) ($) (month)

All Improve housekeeping 2,280 21,050 1

and solid waste

removal

Milk packaging and Rationalize milk 4,650 6,950 8

storage packaging and

increase milk

refrigeration

efficiency

White cheese Reuse whey 0 350 Immediate

Boiler house Upgrade boiler and 350 3,290 1

restore softening

unit

Garage Collect used oil 90 440 3

Milk receiving and Milk tank level 1,800 22,100 7

pasteurization controls

Food quality valves 11,230

TOTAL 20,400 54,180 5

Cost/benefit analysis

Table 2.17 illustrates the breakdown of the cost/benefit analysis for the cleaner

production techniques implemented in the factory.

The implementation of the above improvements has resulted in daily

savings of 350 kilograms of milk. Additional benefits include:

• Reduced pollution loads.

• The elimination of floor spills.

• Improved hygiene and safety.

• Water consumption dropped by 6%.

• Mazot consumption has decreased by 10%.

• Solar consumption has decreased by 5%.

• Electricity consumption reduced by 9%.

Textile sector: Sulfur black dyeing in textile companies

Sulfur black dyes are widely used in the textile industry because of low cost and

excellent washing and light fastness properties. Sulfur dyes are water insoluble

and must be first converted to a water-soluble form, by adding a reducing agent,

traditionally sodium sulfide, so that the fibre can absorb the dyes. After dye-

ing the fabric, the dye is converted back to insoluble form with the addition

of an oxidizing agent, often acidified dichromate. This step prevents washing