Page 73 - Materials Chemistry, Second Edition

P. 73

Ch002-P373623.qxd 3/22/07 5:27 PM Page 54

Sustainable Industrial Design and Waste Management

54

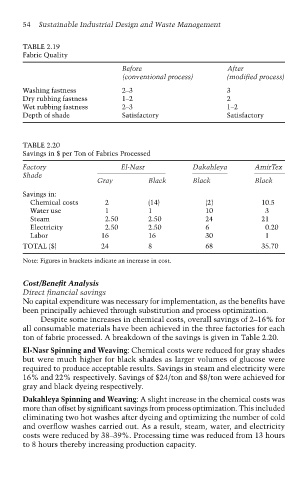

TABLE 2.19

Fabric Quality

Before After

(conventional process) (modified process)

Washing fastness 2–3 3

Dry rubbing fastness 1–2 2

Wet rubbing fastness 2–3 1–2

Depth of shade Satisfactory Satisfactory

TABLE 2.20

Savings in $ per Ton of Fabrics Processed

Factory El-Nasr Dakahleya AmirTex

Shade

Gray Black Black Black

Savings in:

Chemical costs 2 (14) (2) 10.5

Water use 1 1 10 3

Steam 2.50 2.50 24 21

Electricity 2.50 2.50 6 0.20

Labor 16 16 30 1

TOTAL ($) 24 8 68 35.70

Note: Figures in brackets indicate an increase in cost.

Cost/Benefit Analysis

Direct financial savings

No capital expenditure was necessary for implementation, as the benefits have

been principally achieved through substitution and process optimization.

Despite some increases in chemical costs, overall savings of 2–16% for

all consumable materials have been achieved in the three factories for each

ton of fabric processed. A breakdown of the savings is given in Table 2.20.

El-Nasr Spinning and Weaving: Chemical costs were reduced for gray shades

but were much higher for black shades as larger volumes of glucose were

required to produce acceptable results. Savings in steam and electricity were

16% and 22% respectively. Savings of $24/ton and $8/ton were achieved for

gray and black dyeing respectively.

Dakahleya Spinning and Weaving: A slight increase in the chemical costs was

more than offset by significant savings from process optimization. This included

eliminating two hot washes after dyeing and optimizing the number of cold

and overflow washes carried out. As a result, steam, water, and electricity

costs were reduced by 38–39%. Processing time was reduced from 13 hours

to 8 hours thereby increasing production capacity.