Page 177 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 177

150 T h e Fe a s i b i l i t y S t u d y

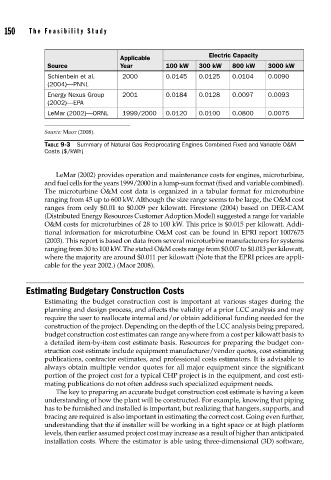

Applicable Electric Capacity

Source Year 100 kW 300 kW 800 kW 3000 kW

Schienbein et al. 2000 0.0145 0.0125 0.0104 0.0090

(2004)—PNNL

Energy Nexus Group 2001 0.0184 0.0128 0.0097 0.0093

(2002)—EPA

LeMar (2002)—ORNL 1999/2000 0.0120 0.0100 0.0800 0.0075

Source: Maor (2008).

TABLE 9-3 Summary of Natural Gas Reciprocating Engines Combined Fixed and Variable O&M

Costs ($/kWh)

LeMar (2002) provides operation and maintenance costs for engines, microturbine,

and fuel cells for the years 1999/2000 in a lump-sum format (fixed and variable combined).

The microturbine O&M cost data is organized in a tabular format for microturbine

ranging from 45 up to 600 kW. Although the size range seems to be large, the O&M cost

ranges from only $0.01 to $0.009 per kilowatt. Firestone (2004) based on DER-CAM

(Distributed Energy Resources Customer Adoption Model) suggested a range for variable

O&M costs for microturbines of 28 to 100 kW. This price is $0.015 per kilowatt. Addi-

tional information for microturbine O&M cost can be found in EPRI report 1007675

(2003). This report is based on data from several microturbine manufacturers for systems

ranging from 30 to 100 kW. The stated O&M costs range from $0.007 to $0.013 per kilowatt,

where the majority are around $0.011 per kilowatt (Note that the EPRI prices are appli-

cable for the year 2002.) (Maor 2008).

Estimating Budgetary Construction Costs

Estimating the budget construction cost is important at various stages during the

planning and design process, and affects the validity of a prior LCC analysis and may

require the user to reallocate internal and/or obtain additional funding needed for the

construction of the project. Depending on the depth of the LCC analysis being prepared,

budget construction cost estimates can range anywhere from a cost per kilowatt basis to

a detailed item-by-item cost estimate basis. Resources for preparing the budget con-

struction cost estimate include equipment manufacturer/vendor quotes, cost estimating

publications, contractor estimates, and professional costs estimators. It is advisable to

always obtain multiple vendor quotes for all major equipment since the significant

portion of the project cost for a typical CHP project is in the equipment, and cost esti-

mating publications do not often address such specialized equipment needs.

The key to preparing an accurate budget construction cost estimate is having a keen

understanding of how the plant will be constructed. For example, knowing that piping

has to be furnished and installed is important, but realizing that hangers, supports, and

bracing are required is also important in estimating the correct cost. Going even further,

understanding that the if installer will be working in a tight space or at high platform

levels, then earlier assumed project cost may increase as a result of higher than anticipated

installation costs. Where the estimator is able using three-dimensional (3D) software,