Page 60 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 60

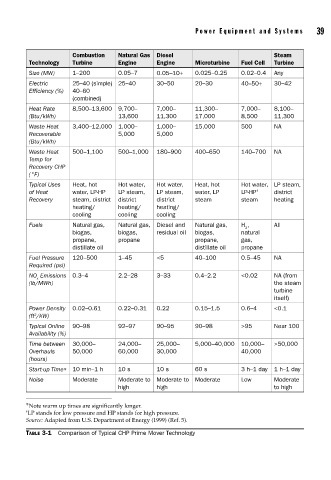

Power Equipment and Systems 39

Combustion Natural Gas Diesel Steam

Technology Turbine Engine Engine Microturbine Fuel Cell Turbine

Size (MW) 1–200 0.05–7 0.05–10+ 0.025–0.25 0.02–0.4 Any

Electric 25–40 (simple) 25–40 30–50 20–30 40–50+ 30–42

Efficiency (%) 40–60

(combined)

Heat Rate 8,500–13,600 9,700– 7,000– 11,300– 7,000– 8,100–

(Btu/kWh) 13,600 11,300 17,000 8,500 11,300

Waste Heat 3,400–12,000 1,000– 1,000– 15,000 500 NA

Recoverable 5,000 5,000

(Btu/kWh)

Waste Heat 500–1,100 500–1,000 180–900 400–650 140–700 NA

Temp for

Recovery CHP

(°F)

Typical Uses Heat, hot Hot water, Hot water, Heat, hot Hot water, LP steam,

of Heat water, LP-HP LP steam, LP steam, water, LP LP-HP † district

Recovery steam, district district district steam steam heating

heating/ heating/ heating/

cooling cooling cooling

Fuels Natural gas, Natural gas, Diesel and Natural gas, H , All

2

biogas, biogas, residual oil biogas, natural

propane, propane propane, gas,

distillate oil distillate oil propane

Fuel Pressure 120–500 1–45 <5 40–100 0.5–45 NA

Required (psi)

NO Emissions 0.3–4 2.2–28 3–33 0.4–2.2 <0.02 NA (from

x

(lb/MWh) the steam

turbine

itself)

Power Density 0.02–0.61 0.22–0.31 0.22 0.15–1.5 0.6–4 <0.1

2

(ft /kW)

Typical Online 90–98 92–97 90–95 90–98 >95 Near 100

Availability (%)

Time between 30,000– 24,000– 25,000– 5,000–40,000 10,000– >50,000

Overhauls 50,000 60,000 30,000 40,000

(hours)

Start-up Time∗ 10 min–1 h 10 s 10 s 60 s 3 h–1 day 1 h–1 day

Noise Moderate Moderate to Moderate to Moderate Low Moderate

high high to high

∗ Note warm up times are significantly longer.

† LP stands for low pressure and HP stands for high pressure.

Source: Adapted from U.S. Department of Energy (1999) (Ref. 5).

TABLE 3-1 Comparison of Typical CHP Prime Mover Technology