Page 76 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 76

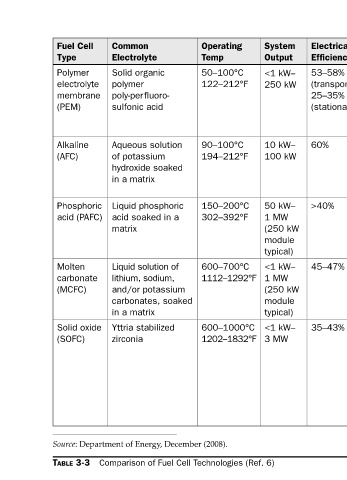

Electrical CHP Advantages Efficiency Applications Efficiency Solid electrolyte reduces Backup power 70–90% 53–58% corrosion and electrolyte Portable power (low-grade (transportation) management problems Small distributed waste 25–35% Low temperature generation heat) (stationary) Quick start-up Transportation Specialty vehicles Cathode reac

System Output <1 kW– 250 kW 10 kW– 100 kW 50 kW– 1 MW (250 kW module typical) <1 kW– 1 MW (250 kW module typical) <1 kW– 3 MW

Operating Temp 50–100°C 122–212°F 90–100°C 194–212°F 150–200°C 302–392°F 600–700°C 1112–1292°F 600–1000°C 1202–1832°F Comparison of Fuel Cell Technologies (Ref. 6)

Common Electrolyte Solid organic polymer poly-perfluoro- sulfonic acid Aqueous solution of potassium hydroxide soaked in a matrix Liquid phosphoric acid soaked in a matrix Liquid solution of lithium, sodium, and/or potassium carbonates, soaked in a matrix Yttria stabilized zirconia Source: Department of Energy, December

Fuel Cell Type Polymer electrolyte membrane (PEM) Alkaline (AFC) Phosphoric acid (PAFC) Molten carbonate (MCFC) Solid oxide (SOFC) TABLE 3-3