Page 77 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 77

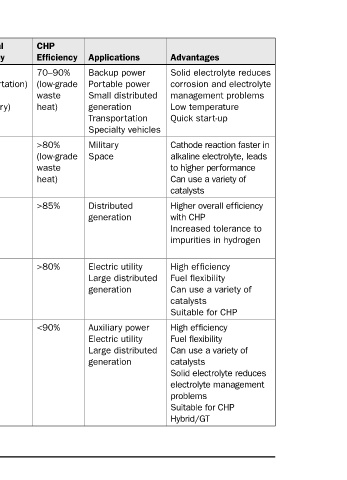

Advantages Solid electrolyte reduces corrosion and electrolyte management problems Low temperature Quick start-up Cathode reaction faster in alkaline electrolyte, leads to higher performance Can use a variety of catalysts Higher overall efficiency with CHP Increased tolerance to impurities in hydrogen High efficiency Fuel flexibility

Efficiency Applications Backup power Portable power Small distributed generation Transportation Specialty vehicles Military Space Distributed generation utility Electric Large distributed generation power Auxiliary Electric utility Large distributed generation

CHP 70–90% (low-grade waste heat) >80% (low-grade waste heat) >85% >80% <90%

Electrical Efficiency 53–58% (transportation) 25–35% (stationary) 60% >40% 45–47% 35–43%

System Output <1 kW– 250 kW 10 kW– 100 kW 50 kW– 1 MW (250 kW module typical) <1 kW– 1 MW (250 kW module typical) <1 kW– 3 MW

Operating Temp 50–100°C 122–212°F 90–100°C 194–212°F 150–200°C 302–392°F 600–700°C 1112–1292°F 600–1000°C 1202–1832°F Comparison of Fuel Cell Technologies (Ref. 6)

Common Electrolyte Solid organic polymer poly-perfluoro- sulfonic acid Aqueous solution of potassium hydroxide soaked in a matrix Liquid phosphoric acid soaked in a matrix Liquid solution of lithium, sodium, and/or potassium carbonates, soaked in a matrix Yttria stabilized zirconia Source: Department of Energy, December

Fuel Cell Type Polymer electrolyte membrane (PEM) Alkaline (AFC) Phosphoric acid (PAFC) Molten carbonate (MCFC) Solid oxide (SOFC) TABLE 3-3