Page 127 - Synthetic Fuels Handbook

P. 127

FUELS FROM TAR SAND BITUMEN 113

composition of the Alberta bitumen does not appear to be influenced by the proportion of

bitumen in the tar sand or by the particle size of the tar sand minerals.

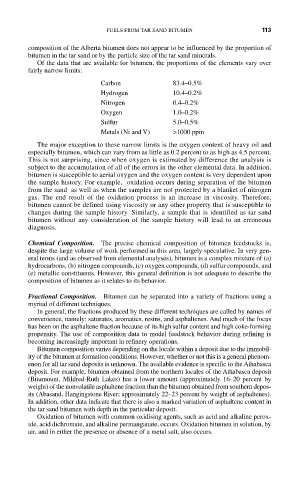

Of the data that are available for bitumen, the proportions of the elements vary over

fairly narrow limits:

Carbon 83.4–0.5%

Hydrogen 10.4–0.2%

Nitrogen 0.4–0.2%

Oxygen 1.0–0.2%

Sulfur 5.0–0.5%

Metals (Ni and V) >1000 ppm

The major exception to these narrow limits is the oxygen content of heavy oil and

especially bitumen, which can vary from as little as 0.2 percent to as high as 4.5 percent.

This is not surprising, since when oxygen is estimated by difference the analysis is

subject to the accumulation of all of the errors in the other elemental data. In addition,

bitumen is susceptible to aerial oxygen and the oxygen content is very dependent upon

the sample history. For example, oxidation occurs during separation of the bitumen

from the sand as well as when the samples are not protected by a blanket of nitrogen

gas. The end result of the oxidation process is an increase in viscosity. Therefore,

bitumen cannot be defined using viscosity or any other property that is susceptible to

changes during the sample history. Similarly, a sample that is identified as tar sand

bitumen without any consideration of the sample history will lead to an erroneous

diagnosis.

Chemical Composition. The precise chemical composition of bitumen feedstocks is,

despite the large volume of work performed in this area, largely speculative. In very gen-

eral terms (and as observed from elemental analyses), bitumen is a complex mixture of (a)

hydrocarbons, (b) nitrogen compounds, (c) oxygen compounds, (d) sulfur compounds, and

(e) metallic constituents. However, this general definition is not adequate to describe the

composition of bitumen as it relates to its behavior.

Fractional Composition. Bitumen can be separated into a variety of fractions using a

myriad of different techniques.

In general, the fractions produced by these different techniques are called by names of

convenience, namely: saturates, aromatics, resins, and asphaltenes. And much of the focus

has been on the asphaltene fraction because of its high sulfur content and high coke-forming

propensity. The use of composition data to model feedstock behavior during refining is

becoming increasingly important in refinery operations.

Bitumen composition varies depending on the locale within a deposit due to the immobil-

ity of the bitumen at formation conditions. However, whether or not this is a general phenom-

enon for all tar sand deposits is unknown. The available evidence is specific to the Athabasca

deposit. For example, bitumen obtained from the northern locales of the Athabasca deposit

(Bitumount, Mildred-Ruth Lakes) has a lower amount (approximately 16–20 percent by

weight) of the nonvolatile asphaltene fraction than the bitumen obtained from southern depos-

its (Abasand, Hangingstone River; approximately 22–23 percent by weight of asphaltenes).

In addition, other data indicate that there is also a marked variation of asphaltene content in

the tar sand bitumen with depth in the particular deposit.

Oxidation of bitumen with common oxidising agents, such as acid and alkaline perox-

ide, acid dichromate, and alkaline permanganate, occurs. Oxidation bitumen in solution, by

air, and in either the presence or absence of a metal salt, also occurs.