Page 152 - Synthetic Fuels Handbook

P. 152

138 CHAPTER FIVE

In the current context, coal mining depends on the following criteria: (a) seam thickness,

(b) the overburden thickness, (c) the ease of removal of the overburden (surface mining),

(d) the ease with which a shaft can be sunk to reach the coal seam (underground mining), (e) the

amount of coal extracted relative to the amount that cannot be removed, and (f) the market

demand for the coal.

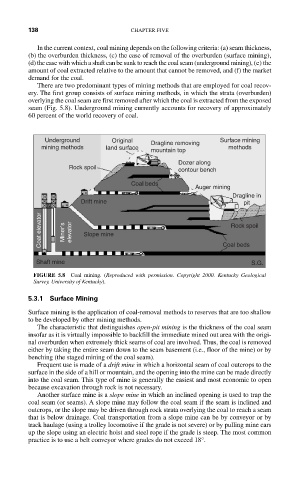

There are two predominant types of mining methods that are employed for coal recov-

ery. The first group consists of surface mining methods, in which the strata (overburden)

overlying the coal seam are first removed after which the coal is extracted from the exposed

seam (Fig. 5.8). Underground mining currently accounts for recovery of approximately

60 percent of the world recovery of coal.

Underground Original Dragline removing Surface mining

mining methods land surface mountain top methods

Dozer along

Rock spoil contour bench

Coal beds

Auger mining

Dragline in

Drift mine pit

Coat elevator Miner’s elevator Slope mine Coal beds

Rock spoil

Shaft mine S.G.

FIGURE 5.8 Coal mining. (Reproduced with permission. Copyright 2000. Kentucky Geological

Survey, University of Kentucky).

5.3.1 Surface Mining

Surface mining is the application of coal-removal methods to reserves that are too shallow

to be developed by other mining methods.

The characteristic that distinguishes open-pit mining is the thickness of the coal seam

insofar as it is virtually impossible to backfill the immediate mined out area with the origi-

nal overburden when extremely thick seams of coal are involved. Thus, the coal is removed

either by taking the entire seam down to the seam basement (i.e., floor of the mine) or by

benching (the staged mining of the coal seam).

Frequent use is made of a drift mine in which a horizontal seam of coal outcrops to the

surface in the side of a hill or mountain, and the opening into the mine can be made directly

into the coal seam. This type of mine is generally the easiest and most economic to open

because excavation through rock is not necessary.

Another surface mine is a slope mine in which an inclined opening is used to trap the

coal seam (or seams). A slope mine may follow the coal seam if the seam is inclined and

outcrops, or the slope may be driven through rock strata overlying the coal to reach a seam

that is below drainage. Coal transportation from a slope mine can be by conveyor or by

track haulage (using a trolley locomotive if the grade is not severe) or by pulling mine cars

up the slope using an electric hoist and steel rope if the grade is steep. The most common

practice is to use a belt conveyor where grades do not exceed 18°.