Page 157 - Synthetic Fuels Handbook

P. 157

FUELS FROM COAL 143

Power & steam Coal Iron reduction

Naphtha Fischer- Gasification Fuel/town gas

tropsch

Waxes liquids Ammonia

Synthesis gas H 2 & urea

Diesel/jet/gas fuels

Methanol Dimethyl ether

Synthetic natural gas

Methyl acetate

Ethylene

Acetic acid &

propylene

Acetate

VAM Ketene esters

Oxo chemicals

PVA Diketene &

derivatives Acetic anhydride Polyolefins

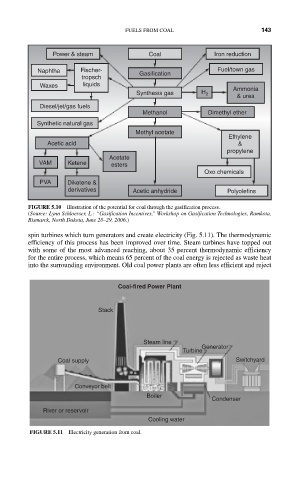

FIGURE 5.10 Illustration of the potential for coal through the gasification process.

(Source: Lynn Schloesser, L.: “Gasification Incentives,” Workshop on Gasification Technologies, Ramkota,

Bismarck, North Dakota, June 28–29, 2006.)

spin turbines which turn generators and create electricity (Fig. 5.11). The thermodynamic

efficiency of this process has been improved over time. Steam turbines have topped out

with some of the most advanced reaching, about 35 percent thermodynamic efficiency

for the entire process, which means 65 percent of the coal energy is rejected as waste heat

into the surrounding environment. Old coal power plants are often less efficient and reject

Coal-fired Power Plant

Stack

Steam line

Generator

Turbine

Coal supply Switchyard

Conveyor belt

Boiler

Condenser

River or reservoir

Cooling water

FIGURE 5.11 Electricity generation from coal.