Page 160 - Synthetic Fuels Handbook

P. 160

146 CHAPTER FIVE

plants, especially air emissions, and the potential for lower-cost control of green-

house gases than other coal-based systems. Fluctuations in the costs associated with

natural-gas-based power, which is viewed as a major competitor to coal based power,

can also play a role.

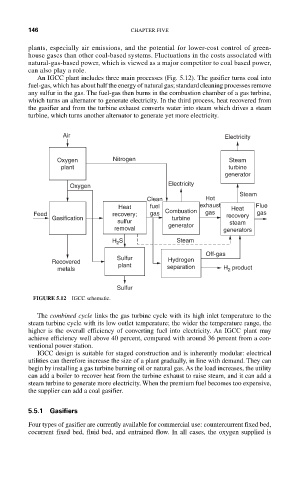

An IGCC plant includes three main processes (Fig. 5.12). The gasifier turns coal into

fuel-gas, which has about half the energy of natural gas; standard cleaning processes remove

any sulfur in the gas. The fuel-gas then burns in the combustion chamber of a gas turbine,

which turns an alternator to generate electricity. In the third process, heat recovered from

the gasifier and from the turbine exhaust converts water into steam which drives a steam

turbine, which turns another alternator to generate yet more electricity.

Air Electricity

Oxygen Nitrogen Steam

plant turbine

generator

Oxygen Electricity

Steam

Clean Hot

Heat fuel exhaust Heat Flue

Feed recovery; gas Combustion gas recovery gas

Gasification turbine

sulfur steam

removal generator generators

H S Steam

2

Off-gas

Sulfur Hydrogen

Recovered plant

metals separation H product

2

Sulfur

FIGURE 5.12 IGCC schematic.

The combined cycle links the gas turbine cycle with its high inlet temperature to the

steam turbine cycle with its low outlet temperature; the wider the temperature range, the

higher is the overall efficiency of converting fuel into electricity. An IGCC plant may

achieve efficiency well above 40 percent, compared with around 36 percent from a con-

ventional power station.

IGCC design is suitable for staged construction and is inherently modular: electrical

utilities can therefore increase the size of a plant gradually, in line with demand. They can

begin by installing a gas turbine burning oil or natural gas. As the load increases, the utility

can add a boiler to recover heat from the turbine exhaust to raise steam, and it can add a

steam turbine to generate more electricity. When the premium fuel becomes too expensive,

the supplier can add a coal gasifier.

5.5.1 Gasifiers

Four types of gasifier are currently available for commercial use: countercurrent fixed bed,

cocurrent fixed bed, fluid bed, and entrained flow. In all cases, the oxygen supplied is