Page 196 - Synthetic Fuels Handbook

P. 196

182 CHAPTER SIX

Kinetic studies (Scouten, 1990) indicate that below 500°C the kerogen (organic matter)

decomposes into bitumen with subsequent decomposition into oil, gas, and carbon residue.

The actual kinetic picture is influenced by the longer time required to heat the organic

material which is dispersed throughout the mineral matrix, and to the increased resistance

to the outward diffusion of the products by the matrix which does not decompose. From the

practical standpoint of oil shale retorting, the rate of oil production is the important aspect

of kerogen decomposition.

The processes for producing oil from oil shale involve heating (retorting) the shale to

convert the organic kerogen to a raw shale oil (Janka and Dennison, 1979; Rattien and

Eaton, 1976; Burnham and McConaghy, 2006). Conversion of kerogen to oil without

the agency of heat has not yet been proven commercially, although there are schemes for

accomplishing such a task but, in spite of claims to the contrary, these have not moved into

the viable commercial or even demonstration stage.

Thus, there are two basic oil shale retorting approaches: (a) mining followed by retorting

at the surface and (b) in situ retorting, that is, heating the shale in place underground. Each

method, in turn, can be further categorized according to the method of heating (Table 6.4)

(Burnham and McConaghy 2006).

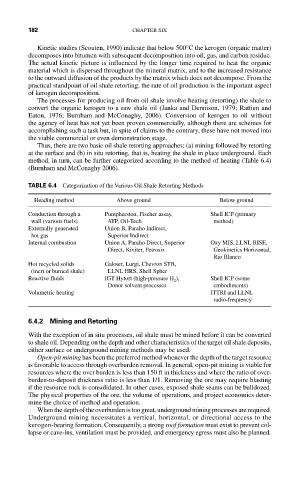

TABLE 6.4 Categorization of the Various Oil Shale Retorting Methods

Heading method Above ground Below ground

Conduction through a Pumpherston, Fischer assay, Shell ICP (primary

wall (various fuels) ATP, Oil-Tech method)

Externally generated Union B, Paraho Indirect,

hot gas Superior Indirect

Internal combustion Union A, Paraho Direct, Superior Oxy MIS, LLNL RISE,

Direct, Kiviter, Petrosix Geokinetics Horizontal,

Rio Blanco

Hot recycled solids Galoter, Lurgi, Chevron STB,

(inert or burned shale) LLNL HRS, Shell Spher

Reactive fluids IGT Hytort (high-pressure H ), Shell ICP (some

2

Donor solvent processes embodiments)

Volumetric heating ITTRI and LLNL

radio-frequency

6.4.2 Mining and Retorting

With the exception of in situ processes, oil shale must be mined before it can be converted

to shale oil. Depending on the depth and other characteristics of the target oil shale deposits,

either surface or underground mining methods may be used.

Open-pit mining has been the preferred method whenever the depth of the target resource

is favorable to access through overburden removal. In general, open-pit mining is viable for

resources where the over burden is less than 150 ft in thickness and where the ratio of over-

burden-to-deposit thickness ratio is less than 1/1. Removing the ore may require blasting

if the resource rock is consolidated. In other cases, exposed shale seams can be bulldozed.

The physical properties of the ore, the volume of operations, and project economics deter-

mine the choice of method and operation.

When the depth of the overburden is too great, underground mining processes are required.

Underground mining necessitates a vertical, horizontal, or directional access to the

kerogen-bearing formation. Consequently, a strong roof formation must exist to prevent col-

lapse or cave-ins, ventilation must be provided, and emergency egress must also be planned.