Page 201 - Synthetic Fuels Handbook

P. 201

FUELS FROM OIL SHALE 187

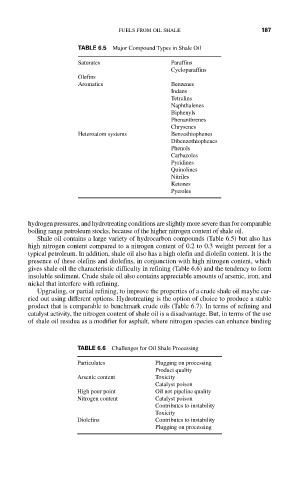

TABLE 6.5 Major Compound Types in Shale Oil

Saturates Paraffins

Cycloparaffins

Olefins

Aromatics Benzenes

Indans

Tetralins

Naphthalenes

Biphenyls

Phenanthrenes

Chrysenes

Heteroatom systems Benzothiophenes

Dibenzothiophenes

Phenols

Carbazoles

Pyridines

Quinolines

Nitriles

Ketones

Pyrroles

hydrogen pressures, and hydrotreating conditions are slightly more severe than for comparable

boiling range petroleum stocks, because of the higher nitrogen content of shale oil.

Shale oil contains a large variety of hydrocarbon compounds (Table 6.5) but also has

high nitrogen content compared to a nitrogen content of 0.2 to 0.3 weight percent for a

typical petroleum. In addition, shale oil also has a high olefin and diolefin content. It is the

presence of these olefins and diolefins, in conjunction with high nitrogen content, which

gives shale oil the characteristic difficulty in refining (Table 6.6) and the tendency to form

insoluble sediment. Crude shale oil also contains appreciable amounts of arsenic, iron, and

nickel that interfere with refining.

Upgrading, or partial refining, to improve the properties of a crude shale oil maybe car-

ried out using different options. Hydrotreating is the option of choice to produce a stable

product that is comparable to benchmark crude oils (Table 6.7). In terms of refining and

catalyst activity, the nitrogen content of shale oil is a disadvantage. But, in terms of the use

of shale oil residua as a modifier for asphalt, where nitrogen species can enhance binding

TABLE 6.6 Challenges for Oil Shale Processing

Particulates Plugging on processing

Product quality

Arsenic content Toxicity

Catalyst poison

High pour point Oil not pipeline quality

Nitrogen content Catalyst poison

Contributes to instability

Toxicity

Diolefins Contributes to instability

Plugging on processing