Page 230 - Synthetic Fuels Handbook

P. 230

216 CHAPTER SEVEN

Syngas inlet

Gas

outlet Gas

outlet Gas

outlet

Hopper

Catalyst

tubes Catalyst

Slurry Wax

Steam bed out

Steam

Catalyst

Stanoppe bed

Cooling Cooling

Gas

water water

outlet Syngas

Syngas

inlet

inlet

Syngas

Wax outer

inlet

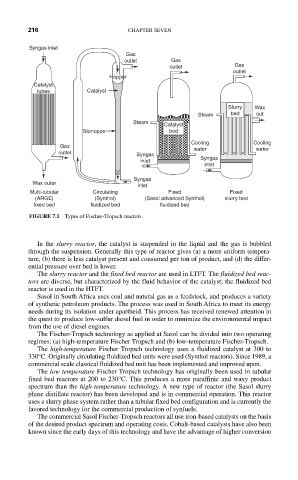

Multi-tubular Circulating Fixed Fixed

(ARGE) (Synthol) (Sasol advanced Synthol) slurry bed

fixed bed fluidized bed fluidized bed

FIGURE 7.1 Types of Fischer-Tropsch reactors.

In the slurry reactor, the catalyst is suspended in the liquid and the gas is bubbled

through the suspension. Generally this type of reactor gives (a) a more uniform tempera-

ture, (b) there is less catalyst present and consumed per ton of product, and (d) the differ-

ential pressure over bed is lower.

The slurry reactor and the fixed bed reactor are used in LTFT. The fluidized bed reac-

tors are diverse, but characterized by the fluid behavior of the catalyst; the fluidized bed

reactor is used in the HTFT.

Sasol in South Africa uses coal and natural gas as a feedstock, and produces a variety

of synthetic petroleum products. The process was used in South Africa to meet its energy

needs during its isolation under apartheid. This process has received renewed attention in

the quest to produce low-sulfur diesel fuel in order to minimize the environmental impact

from the use of diesel engines.

The Fischer-Tropsch technology as applied at Sasol can be divided into two operating

regimes: (a) high-temperature Fischer Tropsch and (b) low-temperature Fischer-Tropsch.

The high-temperature Fischer Tropsch technology uses a fluidized catalyst at 300 to

330°C. Originally circulating fluidized bed units were used (Synthol reactors). Since 1989, a

commercial scale classical fluidized bed unit has been implemented and improved upon.

The low temperature Fischer Tropsch technology has originally been used in tubular

fixed bed reactors at 200 to 230°C. This produces a more paraffinic and waxy product

spectrum than the high-temperature technology. A new type of reactor (the Sasol slurry

phase distillate reactor) has been developed and is in commercial operation. This reactor

uses a slurry phase system rather than a tubular fixed bed configuration and is currently the

favored technology for the commercial production of synfuels.

The commercial Sasol Fischer-Tropsch reactors all use iron-based catalysts on the basis

of the desired product spectrum and operating costs. Cobalt-based catalysts have also been

known since the early days of this technology and have the advantage of higher conversion