Page 267 - Synthetic Fuels Handbook

P. 267

FUELS FROM BIOMASS 253

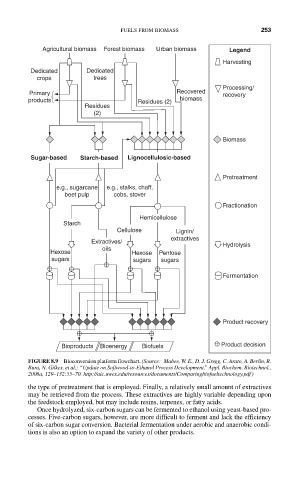

Agricultural biomass Forest biomass Urban biomass Legend

Harvesting

Dedicated Dedicated

crops trees

Processing/

Primary Recovered recovery

products Residues (2) biomass

Residues

(2)

Biomass

Sugar-based Starch-based Lignocellulosic-based

Pretreatment

e.g., sugarcane e.g., stalks, chaff,

beet pulp cobs, stover

Fractionation

Hemicellulose

Starch

Cellulose Lignin/

extractives

Extractives/ Hydrolysis

oils

Hexose Hexose Pentose

sugars sugars sugars

Fermentation

Product recovery

Bioproducts Bioenergy Biofuels Product decision

FIGURE 8.9 Bioconversion platform flowchart. (Source: Mabee, W. E., D. J. Gregg, C. Arato, A. Berlin, R.

Bura, N. Gilkes, et al.: “Update on Softwood-to-Ethanol Process Development,” Appl. Biochem. Biotechnol.,

2006a, 129–132:55–70. http://aic.uwex.edu/resources/documents/Comparingbiofueltechnology.pdf )

the type of pretreatment that is employed. Finally, a relatively small amount of extractives

may be retrieved from the process. These extractives are highly variable depending upon

the feedstock employed, but may include resins, terpenes, or fatty acids.

Once hydrolyzed, six-carbon sugars can be fermented to ethanol using yeast-based pro-

cesses. Five-carbon sugars, however, are more difficult to ferment and lack the efficiency

of six-carbon sugar conversion. Bacterial fermentation under aerobic and anaerobic condi-

tions is also an option to expand the variety of other products.