Page 262 - Synthetic Fuels Handbook

P. 262

248 CHAPTER EIGHT

Feedstocks: vegetable oils, Purification Methanol

animal fats, (remove water, recovery Biodiesel

used cooking oils unroaclod alcohol)

Remove water and

contaminants

(animal fats, used Crude biodiesel

cooking oils only)

Heat

Add alcohol

Recycled methanol

(methanol) and

catalyst {NaOH}

Phase Methanol

Transesterfication separation recovery Crude glycerin

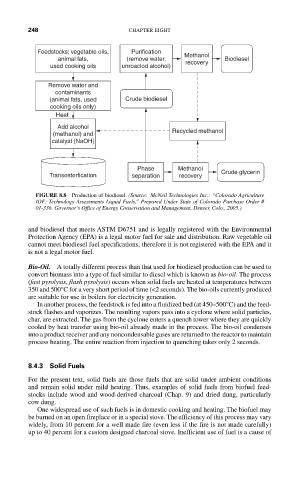

FIGURE 8.8 Production of biodiesel. (Source: McNeil Technologies Inc.: “Colorado Agriculture

IOF: Technology Assessments Liquid Fuels,” Prepared Under State of Colorado Purchase Order #

01-336. Governor’s Office of Energy Conservation and Management, Denver, Colo., 2005.)

and biodiesel that meets ASTM D6751 and is legally registered with the Environmental

Protection Agency (EPA) is a legal motor fuel for sale and distribution. Raw vegetable oil

cannot meet biodiesel fuel specifications, therefore it is not registered with the EPA and it

is not a legal motor fuel.

Bio-Oil. A totally different process than that used for biodiesel production can be used to

convert biomass into a type of fuel similar to diesel which is known as bio-oil. The process

(fast pyrolysis, flash pyrolysis) occurs when solid fuels are heated at temperatures between

350 and 500°C for a very short period of time (<2 seconds). The bio-oils currently produced

are suitable for use in boilers for electricity generation.

In another process, the feedstock is fed into a fluidized bed (at 450–500°C) and the feed-

stock flashes and vaporizes. The resulting vapors pass into a cyclone where solid particles,

char, are extracted. The gas from the cyclone enters a quench tower where they are quickly

cooled by heat transfer using bio-oil already made in the process. The bio-oil condenses

into a product receiver and any noncondensable gases are returned to the reactor to maintain

process heating. The entire reaction from injection to quenching takes only 2 seconds.

8.4.3 Solid Fuels

For the present text, solid fuels are those fuels that are solid under ambient conditions

and remain solid under mild heating. Thus, examples of solid fuels from biofuel feed-

stocks include wood and wood-derived charcoal (Chap. 9) and dried dung, particularly

cow dung.

One widespread use of such fuels is in domestic cooking and heating. The biofuel may

be burned on an open fireplace or in a special stove. The efficiency of this process may vary

widely, from 10 percent for a well made fire (even less if the fire is not made carefully)

up to 40 percent for a custom designed charcoal stove. Inefficient use of fuel is a cause of