Page 259 - Synthetic Fuels Handbook

P. 259

FUELS FROM BIOMASS 245

Feedstock Feedstock

handling

Lignin Lignin

intermediates products

Gasification/ Feedstock Pretreatment Sugar

pyrolysis intermediates

Hydrogen &

bioproducts

Gas conditioning Enzymatic Sugar

& separation hydrolysis intermediates

of cellulose

Fuels/

products

Multi-sugar Conversion to

Synthesis

fermentation bioproducts

Ethanol Bioproducts

Heat & power recovery

generation

Fuel ethanol

Export electricity

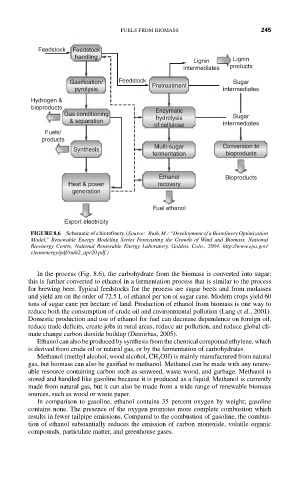

FIGURE 8.6 Schematic of a biorefinery. (Source: Ruth, M.: “Development of a Biorefinery Optimization

Model,” Renewable Energy Modeling Series Forecasting the Growth of Wind and Biomass, National

Bioenergy Centre, National Renewable Energy Laboratory, Golden, Colo., 2004, http://www.epa.gov/

cleanenergy/pdf/ruth2_apr20.pdf.)

In the process (Fig. 8.6), the carbohydrate from the biomass is converted into sugar;

this is further converted to ethanol in a fermentation process that is similar to the process

for brewing beer. Typical feedstocks for the process are sugar beets and from molasses

and yield are on the order of 72.5 L of ethanol per ton of sugar cane. Modern crops yield 60

tons of sugar cane per hectare of land. Production of ethanol from biomass is one way to

reduce both the consumption of crude oil and environmental pollution (Lang et al., 2001).

Domestic production and use of ethanol for fuel can decrease dependence on foreign oil,

reduce trade deficits, create jobs in rural areas, reduce air pollution, and reduce global cli-

mate change carbon dioxide buildup (Demirbas, 2005).

Ethanol can also be produced by synthesis from the chemical compound ethylene, which

is derived from crude oil or natural gas, or by the fermentation of carbohydrates.

Methanol (methyl alcohol, wood alcohol, CH OH) is mainly manufactured from natural

3

gas, but biomass can also be gasified to methanol. Methanol can be made with any renew-

able resource containing carbon such as seaweed, waste wood, and garbage. Methanol is

stored and handled like gasoline because it is produced as a liquid. Methanol is currently

made from natural gas, but it can also be made from a wide range of renewable biomass

sources, such as wood or waste paper.

In comparison to gasoline, ethanol contains 35 percent oxygen by weight; gasoline

contains none. The presence of the oxygen promotes more complete combustion which

results in fewer tailpipe emissions. Compared to the combustion of gasoline, the combus-

tion of ethanol substantially reduces the emission of carbon monoxide, volatile organic

compounds, particulate matter, and greenhouse gases.