Page 326 - Synthetic Fuels Handbook

P. 326

312 CHAPTER TEN

with methanol. Ethyl-t-butyl ether (ETBE) is made by using ethanol instead of methanol.

Thus either ethanol or methanol from either grain or wood could be a factor in making t-

butyl ether octane enhancers. The characteristics of ethers are generally closer to those of

gasoline than those of alcohols.

Ethers are benign in their effect on fuel system materials and are miscible in gasoline;

therefore, they are not subject to phase separation in the presence of water, as are methanol

and ethanol. Ethers are nonpolar. They are of low volatility and thus give low evaporative

emissions.

Alternative fuels from wood, as well as grain, have a potential for being competitive

with gasoline and diesel motor fuels from petroleum, even without subsidization. Today,

ethanol from grain and a slight amount from wood are competing, but only with a large

Federal and some State subsidies. However, environmental and octane-enhancing benefits

of ethanol and other oxygenated fuels that may be produced from grain and wood may

make them worth more than comparisons on fuel value alone would indicate.

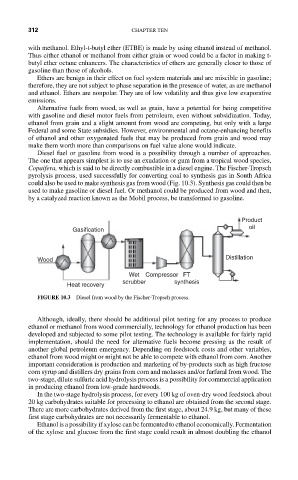

Diesel fuel or gasoline from wood is a possibility through a number of approaches.

The one that appears simplest is to use an exudation or gum from a tropical wood species,

Copaifera, which is said to be directly combustible in a diesel engine. The Fischer-Tropsch

pyrolysis process, used successfully for converting coal to synthesis gas in South Africa

could also be used to make synthesis gas from wood (Fig. 10.3). Synthesis gas could then be

used to make gasoline or diesel fuel. Or methanol could be produced from wood and then,

by a catalyzed reaction known as the Mobil process, be transformed to gasoline.

Product

oil

Gasification

Wood Distillation

Wet Compressor FT

scrubber synthesis

Heat recovery

FIGURE 10.3 Diesel from wood by the Fischer-Tropsch process.

Although, ideally, there should be additional pilot testing for any process to produce

ethanol or methanol from wood commercially, technology for ethanol production has been

developed and subjected to some pilot testing. The technology is available for fairly rapid

implementation, should the need for alternative fuels become pressing as the result of

another global petroleum emergency. Depending on feedstock costs and other variables,

ethanol from wood might or might not be able to compete with ethanol from corn. Another

important consideration is production and marketing of by-products such as high fructose

corn syrup and distillers dry grains from corn and molasses and/or furfural from wood. The

two-stage, dilute sulfuric acid hydrolysis process is a possibility for commercial application

in producing ethanol from low-grade hardwoods.

In the two-stage hydrolysis process, for every 100 kg of oven-dry wood feedstock about

20 kg carbohydrates suitable for processing to ethanol are obtained from the second stage.

There are more carbohydrates derived from the first stage, about 24.9 kg, but many of these

first stage carbohydrates are not necessarily fermentable to ethanol.

Ethanol is a possibility if xylose can be fermented to ethanol economically. Fermentation

of the xylose and glucose from the first stage could result in almost doubling the ethanol