Page 322 - Synthetic Fuels Handbook

P. 322

308 CHAPTER TEN

Trees and shrubs from forests

and non-forest lands

Wood for

non-energy uses

Wood industry

Wood based

products Wood for

Society energy uses

users of wood based products

Woodfuel Woodfuel Woodfuel

recovered indirect direct

Fuelwood (Fw for charcoal-fw- others)

Losses

for

Transformation

charcoal

making

Woodfuel commodities

Import Other product: Black liquor production production Export

Charcoal

Fuelwood

Final energy users

Other product: Black Fuelwood Charcoal

liquor production production

Residential Commercial Industrial Heat and power

sector sector sector generation

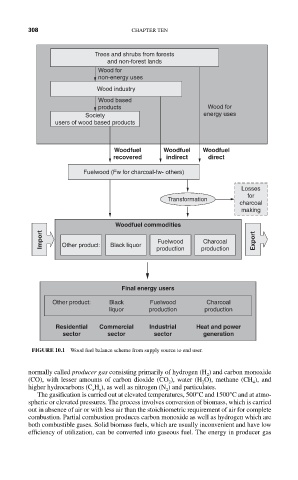

FIGURE 10.1 Wood fuel balance scheme from supply source to end user.

normally called producer gas consisting primarily of hydrogen (H ) and carbon monoxide

2

(CO), with lesser amounts of carbon dioxide (CO ), water (H O), methane (CH ), and

2

4

2

higher hydrocarbons (C H ), as well as nitrogen (N ) and particulates.

x

y

2

The gasification is carried out at elevated temperatures, 500°C and 1500°C and at atmo-

spheric or elevated pressures. The process involves conversion of biomass, which is carried

out in absence of air or with less air than the stoichiometric requirement of air for complete

combustion. Partial combustion produces carbon monoxide as well as hydrogen which are

both combustible gases. Solid biomass fuels, which are usually inconvenient and have low

efficiency of utilization, can be converted into gaseous fuel. The energy in producer gas