Page 155 - TPM A Route to World-Class Performance

P. 155

Applying the TPM improvement plan 133

The costs of this programme are expected to be as follows:

e Labour costs €790

0 Material costs €330

0 Total costs €1120

The major refurbishment tasks are:

0 Replace slide blanket.

0 Replace spindle gasket oil seal and bearing.

e Design workplace stop.

0 Investigate vibration problem and cure.

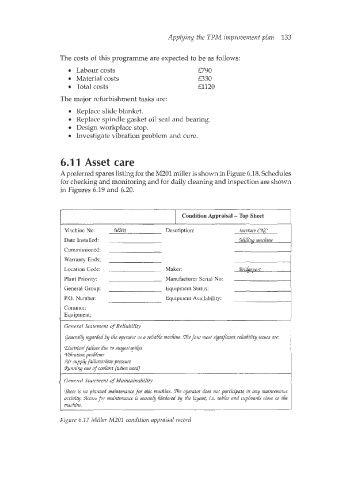

6.11 Asset care

Apreferred spares listing for the M201 miller is shown in Figure 6.18. Schedules

for checking and monitoring and for daily cleaning and inspection are shown

in Figures 6.19 and 6.20.

Condition Appraisal - Top Sheet

Machine No: Mol Description: Interact C%jC

Date Installed: MiiLw machine

Commissioned:

Warranty Ends;

Location Code: Maker:

Plant Priority: Manufacturer Serial No:

General Group: Equipment Status:

P.O. Number: Equipment Availability:

Common

Equipment;

General Statement of Reliability

@neralh ryardedtiy the operator as a reLa6h machine. 17ie four most signqicant reLa6iLty issues are:

‘E(ecm’calfailiure due to suyes/spi&s

?‘&ration pr06&m

Air suppCyfaiiures/lbw pressure

Kunniq out of coolant (whm used

General State.ment of Maintainability

are is no planned maintenance for this machine. fie operator does not particeate in any maintenance

activity. %cas for maintenance is severe@ hindered 6y the layout, i.e. tab& and cup6oards close to the

macfiine.

Figure 6.17 Miller M201 condition appraisal record