Page 62 - TPM A Route to World-Class Performance

P. 62

The top-down and bottom-up realities of TPM 43

which happens to give an average OEE of 83.2 per cent: your target may be

higher.

Start to run the three measures, week by week, on your critical machines,

lines and processes. Build up the notion of the ’best of best’. It is a very

powerful and strong case. If we take the example shown in Figure 3.16, the

best availability (week 2) x the best performance rate (week 3) x the best

quality rate (week 1) gives an OEE of 90.3 per cent. What stops you achieving

the best of best consistently? The answer is that you are not even in control

of the six losses, far less eliminating them. This best of best, however, does

have a high belief level: ‘We have achieved it at least once in the last three

weeks; the problem is we do not achieve each of the three OEE elements

consistently.’

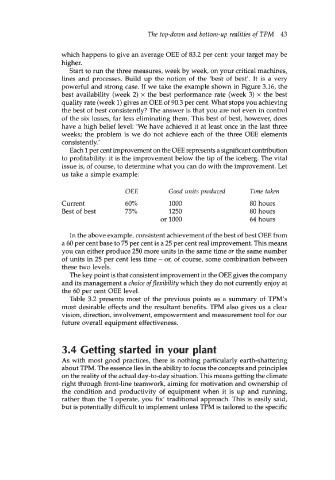

Each 1 per cent improvement on the OEE represents a sigruficant contribution

to profitability: it is the improvement below the tip of the iceberg. The vital

issue is, of course, to determine what you can do with the improvement. Let

us take a simple example:

OEE Good units produced Time taken

Current 60% 1000 80 hours

Best of best 75% 1250 80 hours

or 1000 64 hours

In the above example, consistent achievement of the best of best OEE from

a 60 per cent base to 75 per cent is a 25 per cent real improvement. This means

you can either produce 250 more units in the same time or the same number

of units in 25 per cent less time - or, of course, some combination between

these two levels.

The key point is that consistent improvement in the OEE gives the company

and its management a choice offlexibility which they do not currently enjoy at

the 60 per cent OEE level.

Table 3.2 presents most of the previous points as a summary of TPM’s

most desirable effects and the resultant benefits. TPM also gives us a clear

vision, direction, involvement, empowerment and measurement tool for our

future overall equipment effectiveness.

3.4 Getting started in your plant

As with most good practices, there is nothing particularly earth-shattering

about TPM. The essence lies in the ability to focus the concepts and principles

on the reality of the actual day-to-day situation. This means getting the climate

right through front-line teamwork, aiming for motivation and ownership of

the condition and productivity of equipment when it is up and running,

rather than the ’I operate, you fix’ traditional approach. This is easily said,

but is potentially difficult to implement unless TPM is tailored to the specific