Page 49 - The Combined Finite-Discrete Element Method

P. 49

32 INTRODUCTION

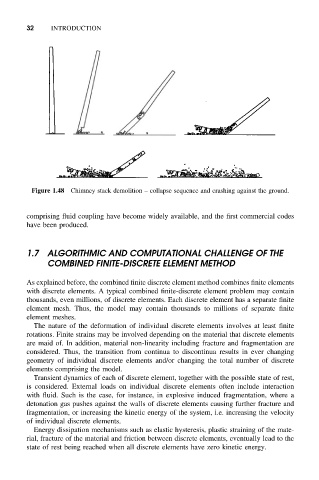

Figure 1.48 Chimney stack demolition – collapse sequence and crashing against the ground.

comprising fluid coupling have become widely available, and the first commercial codes

have been produced.

1.7 ALGORITHMIC AND COMPUTATIONAL CHALLENGE OF THE

COMBINED FINITE-DISCRETE ELEMENT METHOD

As explained before, the combined finite discrete element method combines finite elements

with discrete elements. A typical combined finite-discrete element problem may contain

thousands, even millions, of discrete elements. Each discrete element has a separate finite

element mesh. Thus, the model may contain thousands to millions of separate finite

element meshes.

The nature of the deformation of individual discrete elements involves at least finite

rotations. Finite strains may be involved depending on the material that discrete elements

are maid of. In addition, material non-linearity including fracture and fragmentation are

considered. Thus, the transition from continua to discontinua results in ever changing

geometry of individual discrete elements and/or changing the total number of discrete

elements comprising the model.

Transient dynamics of each of discrete element, together with the possible state of rest,

is considered. External loads on individual discrete elements often include interaction

with fluid. Such is the case, for instance, in explosive induced fragmentation, where a

detonation gas pushes against the walls of discrete elements causing further fracture and

fragmentation, or increasing the kinetic energy of the system, i.e. increasing the velocity

of individual discrete elements.

Energy dissipation mechanisms such as elastic hysteresis, plastic straining of the mate-

rial, fracture of the material and friction between discrete elements, eventually lead to the

state of rest being reached when all discrete elements have zero kinetic energy.