Page 157 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 157

144 I n t e g r a t e d P l a n n i n g O r g a n i z a t i o n a l A s s e s s m e n t 145

Scrap Commonly

rework measured

warranty failure

costs

True

Engineering time failure

management time costs

shop and field downtime Hidden

increased inventory failure

decreased capacity costs

delivery problems

lost orders

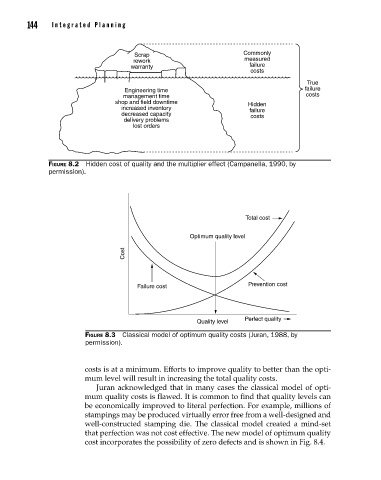

Figure 8.2 Hidden cost of quality and the multiplier effect (Campanella, 1990, by

permission).

Total cost

Optimum quality level

Cost

Failure cost Prevention cost

Quality level Perfect quality

Figure 8.3 Classical model of optimum quality costs (Juran, 1988, by

permission).

costs is at a minimum. Efforts to improve quality to better than the opti

mum level will result in increasing the total quality costs.

Juran acknowledged that in many cases the classical model of opti

mum quality costs is flawed. It is common to find that quality levels can

be economically improved to literal perfection. For example, millions of

stampings may be produced virtually error free from a welldesigned and

wellconstructed stamping die. The classical model created a mindset

that perfection was not cost effective. The new model of optimum quality

cost incorporates the possibility of zero defects and is shown in Fig. 8.4.

08_Pyzdek_Ch08_p137-150.indd 144 11/9/12 5:10 PM