Page 125 - The Jet Engine

P. 125

Fuel system

and pressure increases, the pressurizing valve

moves to progressively admit fuel to the main

manifold and the main orifices. This gives a

combined flow down both manifolds. In this way, the

Duplex and Duple nozzles are able to give effective

atomization over a wider flow range than the Simplex

spray nozzle for the same maximum fuel pressure.

Also, efficient atomization is obtained at the low flows

that may be required at high altitude. In the combined

acceleration and speed control system (para. 51),

the fuel flow to the spray nozzles is apportioned in

the F.F.R.

95. The spill type fuel spray nozzle can be

described as being a Simplex spray nozzle with a

passage from the swirl chamber for spilling fuel

Fig. 10-16 A Simplex fuel spray nozzle. away. With this arrangement it is possible to supply

fuel to the swirl chamber at a high pressure all the

is, at the higher fuel pressures, but was very unsatis- time, As the fuel demand decreases with altitude or

factory at the low pressures required at low engine reduction in engine speed, more fuel is spilled away

speeds and especially at high altitudes. The reason from the swirl Chamber, leaving less to pass through

for this is that the Simplex was, by the nature of its the atomizing orifice. The spill spray nozzles'

design, a 'square law' spray nozzle; that is, the flow constant use of a relatively high pressure means that

through the nozzle is proportional to the square root even at the extremely low fuel flows that occur at

of the pressure drop across it. This meant that if the high altitude there is adequate swirl to provide

minimum pressure for effective atomization was 30 constant and efficient atomization of the fuel.

lb. per square inch, the pressure needed to give

maximum flow would be about 3,000 lb. per square 96. The spill spray nozzle system, however,

inch. The fuel pumps available at that time were involves a somewhat modified type of fuel supply

unable to cope with such high pressures so the and control system from that used with the previous

variable port spray nozzle was developed in an effort types. A means has to be provided for removing the

to overcome the square law effect.

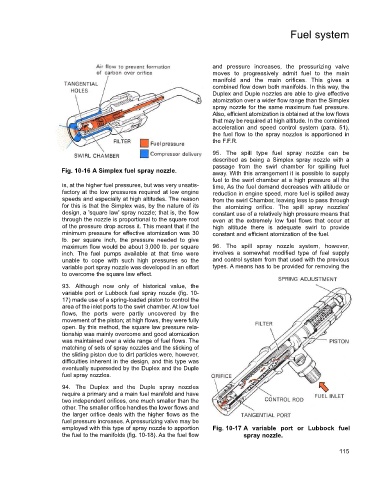

93. Although now only of historical value, the

variable port or Lubbock fuel spray nozzle (fig. 10-

17) made use of a spring-loaded piston to control the

area of the inlet ports to the swirl chamber. At low fuel

flows, the ports were partly uncovered by the

movement of the piston; at high flows, they were fully

open. By this method, the square law pressure rela-

tionship was mainly overcome and good atomization

was maintained over a wide range of fuel flows. The

matching of sets of spray nozzles and the sticking of

the sliding piston due to dirt particles were, however,

difficulties inherent in the design, and this type was

eventually superseded by the Duplex and the Duple

fuel spray nozzles.

94. The Duplex and the Duple spray nozzles

require a primary and a main fuel manifold and have

two independent orifices, one much smaller than the

other. The smaller orifice handles the lower flows and

the larger orifice deals with the higher flows as the

fuel pressure increases. A pressurizing valve may be

employed with this type of spray nozzle to apportion Fig. 10-17 A variable port or Lubbock fuel

the fuel to the manifolds (fig. 10-18). As the fuel flow spray nozzle.

115