Page 124 - The Jet Engine

P. 124

Fuel system

square inch. To drive this pump, as much as 60

horsepower may be required.

87. The fuel pump consists of a rotor assembly

fitted with several plungers, the ends of which project

from their bores and bear on to a non-rotating

camplate. Due to the inclination of the camplate,

movement of the rotor imparts a reciprocating motion

to the plungers, thus producing a pumping action.

The stroke of the plungers is determined by the angle

of inclination of the camplate. The degree of

inclination is varied by the movement of a servo

piston that is mechanically linked to the camplate

and is biased by springs to give the full stroke

position of the plungers. The piston is subjected to

servo pressure on the spring side and on the other

side to pump delivery pressure; thus variations in the

pressure difference across the servo piston cause it

to move with corresponding variations of the

camplate angle and, therefore, pump stroke.

Gear-type fuel pump

88. The gear-type fuel pump (fig. 10-12) is driven

from the engine and its output is directly proportional

to its speed. The fuel flow to the spray nozzles is

controlled by recirculating excess fuel delivery back

to inlet. A spill valve, sensitive to the pressure drop

across the controlling units in the system, opens and

closes as necessary to increase or decrease the

spill.

FUEL SPRAY NOZZLES

89. The final components of the fuel system are the

fuel spray nozzles, which have as their essential

function the task of atomizing or vaporizing the fuel to

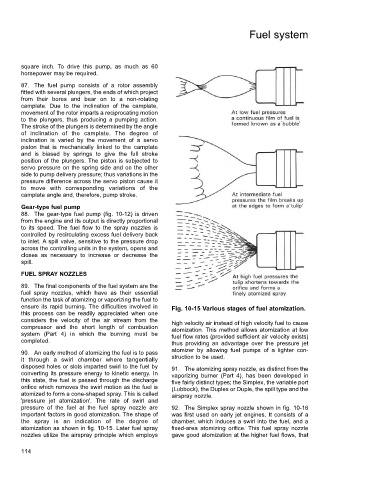

ensure its rapid burning. The difficulties involved in Fig. 10-15 Various stages of fuel atomization.

this process can be readily appreciated when one

considers the velocity of the air stream from the high velocity air instead of high velocity fuel to cause

compressor and the short length of combustion atomization. This method allows atomization at low

system (Part 4) in which the burning must be fuel flow rates (provided sufficient air velocity exists)

completed.

thus providing an advantage over the pressure jet

atomizer by allowing fuel pumps of a lighter con-

90. An early method of atomizing the fuel is to pass

it through a swirl chamber where tangentially struction to be used.

disposed holes or slots imparted swirl to the fuel by 91. The atomizing spray nozzle, as distinct from the

converting its pressure energy to kinetic energy. In vaporizing burner (Part 4), has been developed in

this state, the fuel is passed through the discharge five fairly distinct types; the Simplex, the variable port

orifice which removes the swirl motion as the fuel is (Lubbock), the Duplex or Duple, the spill type and the

atomized to form a cone-shaped spray. This is called airspray nozzle.

'pressure jet atomization'. The rate of swirl and

pressure of the fuel at the fuel spray nozzle are 92. The Simplex spray nozzle shown in fig. 10-16

important factors in good atomization. The shape of was first used on early jet engines. It consists of a

the spray is an indication of the degree of chamber, which induces a swirl into the fuel, and a

atomization as shown in fig. 10-15. Later fuel spray fixed-area atomizing orifice. This fuel spray nozzle

nozzles utilize the airspray principle which employs gave good atomization at the higher fuel flows, that

114